Njengoko sisazi sonke, i-PCB "yibhulorho" yokudibanisa icandelo ngalinye lombane kwaye lelona candelo liphambili kwiimveliso zombane. Ineentlobo ngeentlobo zezicelo, kubandakanywa i-electronics yabathengi, i-automobile electronics, unxibelelwano, amayeza, iprojekthi yomkhosi, i-aerospace kunye nokunye. Kule mihla, i-elektroniki yabathengi kunye ne-automobile electronics bafumana uphuhliso olukhawulezayo kwaye ibe yeyona ndawo iphambili yesicelo. Ngeli xesha, ukuwelda of PCB iye yatsala ingqalelo enkulu evela kubenzi PCB. Ke, zeziphi iintlobo zePCB ezinokusebenza kumatshini we-laser welding? Makhe sihlolisise ngezantsi.

1.Into kufuneka ikwazi ukuwelda

Kuthetha ukuba phantsi kobushushu obufanelekileyo, i-metal to-be--melted metal kunye ne-solder tin inokudibanisa kunye ukuze ibe nomgangatho omhle we-alloy quality. Ayizizo zonke isinyithi ezinokuqina okuhle. Ukuphucula i-weldability yesinyithi, abasebenzisi banokwenza i-tin-plating okanye isilivere-plating kwisinyithi ukuthintela i-oxidation ye-metal surface.

2.Into kufuneka icoceke phezu komhlaba

Ukuze udibanise i-solder tin kunye nezinto eziza kunyibilika, umphezulu wento kufuneka uhlambuluke. Nakwizinto ezintle zokuweldability, ifilimu ye-oxidation okanye ibala leoli inokwenzeka kumphezulu wento. Ke ngoko, ukuqinisekisa umgangatho we-welding, umphezulu wento kufuneka ucoceke.

3.Sebenzisa umgubo wokulinganisa ofanelekileyo

Injongo yokulinganisa ipowder kukususa ifilimu ye-oxidation kwizinto eziza kufakwa kwi-welded. Iindlela ezahlukeneyo zokuwelda kufuneka zamkele umgubo wokukala ohlukeneyo. Kwi-welding echanekileyo ye-elektroniki njenge-PCB, i-rosin kufuneka isetyenziswe njengomgubo wokukala ukuqinisekisa ukuthembeka kwe-welding.

4.Into kufuneka ifudunyezwe kubushushu obufanelekileyo

Ukuba ukushisa kwe-welding kuphantsi kakhulu, i-alloy ayikwazi ukusekwa. Kwaye ukuba ubushushu be-welding buphezulu kakhulu, i-welding flux iya kuhlala kwindawo engeyiyo-eutectic, eya kunciphisa umgangatho we-welding flux kwaye kwimeko embi kakhulu, i-pad kwi-PCB iya kuhla.

5.I-welding ifuna ixesha elifanelekileyo

Ixesha le-welding lithetha ixesha elichithwe kwiikhemikhali kunye nokusabela komzimba kwinkqubo ye-welding. Emva kokugqiba ubushushu be-welding, abasebenzisi kufuneka bathathe isigqibo ngexesha elifanelekileyo le-welding ngokusekelwe kwimilo, umgangatho kunye neempawu zezinto eziza ku-welded. Ukuba ixesha le-welding lide kakhulu, amacandelo okanye iindawo ezidibeneyo zilula ukonakala. Ngokubanzi, indawo nganye akufuneki ithathe ngaphezulu kwemizuzwana emi-5 ngexesha.

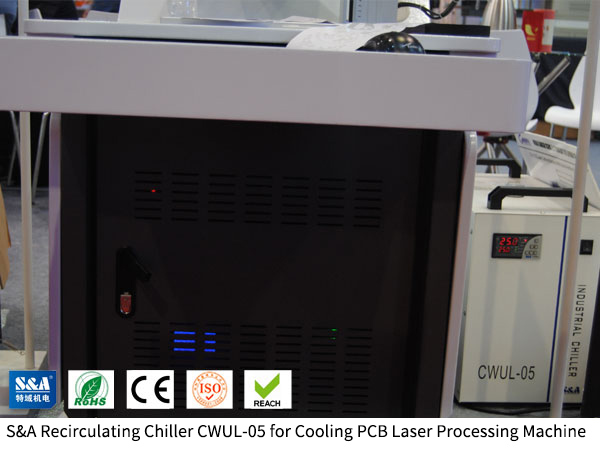

Ukuze ugcine umatshini we-laser we-PCB wokuwelda kweyona nto iphezulu, kufuneka upholiswe ngokufanelekileyo yi-industrial chiller. S&A I-Teyu ibizinikezela kwifriji yeshishini iminyaka eyi-19 kwaye inokubonelela ngee-chillers zeshishini kwiintlobo ezahlukeneyo zoomatshini bokuwelda nge-laser. I-recirculating chillers ibonisa ukukhululeka kokusetyenziswa, ukugcinwa okuphantsi, ubomi obude benkonzo, ukuthembeka okungenakulinganiswa. Umthamo wokupholisa usuka kwi-0.6KW ukuya kwi-30KW, onokuhlangabezana neemfuno zokupholisa kubasebenzisi abahlukeneyo. Ukuba awuqinisekanga ukuba yeyiphi imowudi yokuphinda uyijikeleze ukuze ukhethe, vele usithumele i-imeyile kuyo marketing@teyu.com.cn