Sezvatinoziva tese, PCB ndiro "bhiriji" rekubatanidza chikamu chemagetsi chega chega uye ndicho chikamu chikuru muzvigadzirwa zvemagetsi. Iine zvakasiyana-siyana zvekushandisa, zvinosanganisira zvemagetsi zvevatengi, zvemagetsi zvemotokari, kutaurirana, mishonga, chirongwa chemauto, aerospace uye zvichingodaro. Mazuva ano, zvemagetsi zvevatengi uye zvemotokari zvemagetsi zviri kusangana nekukurumidza kusimudzira uye inova iwo makuru ekushandisa minda. Panguva ino, iyo welding yePCB yakakwezva kutarisisa kukuru kubva kune vanogadzira PCB. Saka, ndeapi marudzi ePCB anogona kushandisa laser welding muchina? Ngatitarisei zvakanyanya pasi apa.

1.Chinhu chinoda kuve chinosungirirwa

Zvinoreva kuti pasi petembiricha yakafanira, simbi yeku-------yakanyungudutswa uye tin inotengeswa zvinogona kusangana pamwechete kuti zvive nemhando yakanaka yemhando yealloy. Haisi simbi yese ine weldability yakanaka. Kuti uvandudze weldability yesimbi, vashandisi vanogona kuita tin-plating kana sirivheri-plating pasimbi kudzivirira oxidation yesimbi.

2.Chinhu chinoda kuchena pamusoro

Kuti ubatanidze tin soldering uye zvinhu zvichanyungudutswa, pamusoro pechinhu chinoda kuchena. Kunyangwe kune yakanaka weldability zvinhu, oxidation firimu kana mafuta tsvina inogona kuitika pane chinhu pamusoro. Naizvozvo, kuvimbisa kunaka kwewelding, chinhu chepamusoro chinofanira kunge chakachena.

3.Shandisa yakakodzera poda yekuyera

Chinangwa chekuyera hupfu ndechekubvisa iyo oxidation firimu pane-ku-we-welded chinhu. Matekinoroji akasiyana-siyana anofanirwa kutora akasiyana scaling poda. Kune welding chaiyo yemagetsi sePCB, rosin inofanirwa kushandiswa sehupfu hwekuyera kuvimbisa kuvimbika kwewelding.

4.Chinhu chinoda kupiswa kusvika kune tembiricha yakakodzera

Kana tembiricha yewelding yakadzikira, iyo alloy haigone kuumbwa. Uye kana tembiricha yewelding yakakwira zvakanyanya, iyo welding flux inogara mune isiri-eutectic mamiriro, ayo anozodzikisa kunaka kwewelding flux uye mumamiriro ezvinhu akaipisisa, padhi paPCB inodonha.

5.The welding inoda nguva yakakodzera nguva

Nguva yewelding inoreva nguva yakashandiswa mumakemikari uye maitiro emuviri mukuita welding. Mushure mekusarudza tembiricha yewelding, vashandisi vanofanirwa kusarudza yakakodzera nguva yewelding zvichienderana nechimiro, mhando uye hunhu hwezvinhu zveku-welded. Kana iyo yelding nguva yakareba, zvikamu kana zvikamu zvakasungirirwa zviri nyore kukuvara. Kazhinji kutaura, nzvimbo yega yega haifanire kutora anopfuura masekonzi mashanu panguva.

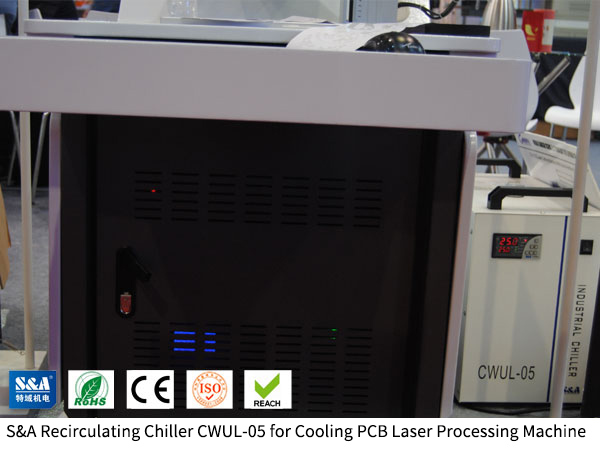

Kuti uchengetedze PCB laser welding muchina payakanyanya kunaka, inoda kunyatsotonhodzwa neindasitiri inotonhora. S&A Teyu anga achizvitsaurira kune indasitiri firiji kwemakore gumi nemapfumbamwe uye anogona kupa maindasitiri anopisa emhando dzakasiyana dzelaser welding michina. Iyo recirculating chillers inoratidzira nyore kushandisa, yakaderera kuchengetedza, hupenyu hurefu hwebasa, kuvimbika kusingaenzaniswi. Iyo yekutonhodza simba inotangira pa0.6KW kusvika 30KW, iyo inogona kusangana nezvinodiwa zvekutonhodza kubva kune vakasiyana vashandisi. Kana iwe usina chokwadi chekuti ndeipi recirculating chiller modhi yekusarudza, ingo e-mail kwatiri marketing@teyu.com.cn