E like me kā mākou e ʻike ai, ʻo PCB ka "alahaka" e hoʻopili i kēlā me kēia ʻāpana uila a ʻo ia ka mea nui i nā huahana uila. Loaʻa iā ia nā ʻano hana like ʻole, e like me nā mea hoʻohana uila, uila uila, kamaʻilio, lāʻau lapaʻau, pāhana koa, aerospace a pēlā aku. I kēia mau lā, ke ʻike nei nā mea uila uila a me nā mea uila kaʻa i ka hoʻomohala wikiwiki loa a lilo i kahua noi nui. I kēia manawa, ua hoʻohuli ʻia ka wili o PCB i ka manaʻo nui mai nā mea hana PCB. No laila, he aha nā ʻano o ka PCB hiki ke hana i ka mīkini welding laser? E nānā pono kākou ma lalo nei.

1. Pono e weldable ka mea

ʻO ia hoʻi, ma lalo o ka mahana kūpono, hiki ke hoʻohui ʻia ka metala e hoʻoheheʻe ʻia a me ka tin soldering e loaʻa ai ka maikaʻi maikaʻi o ke ʻano huila. ʻAʻole maikaʻi ka weldability o kēlā me kēia metala. No ka hoʻomaikaʻi ʻana i ka weldability o ka metala, hiki i nā mea hoʻohana ke hana i ka tin-plating a i ʻole ke kala-plating ma luna o ka metala e pale ai i ka oxidation o ka ʻili metala.

2. Pono ka mea maʻemaʻe ma luna o ka ʻili

No ka hoʻohui ʻana i ka ipu hao a me nā mea e hoʻoheheʻe ʻia, pono e maʻemaʻe ka ʻili o ka mea. ʻOiai no nā mea hoʻoheheʻe maikaʻi, hiki ke loaʻa ke kiʻi oxidation a i ʻole ka ʻaila hinu ma ka ʻili o ka mea. No laila, e hōʻoiaʻiʻo i ka maikaʻi o ka welding, pono e maʻemaʻe ka ʻili o ka mea.

3.E hoʻohana i ka pauka scaling kūpono

ʻO ke kumu o ka scaling pauda ʻo ia ka wehe ʻana i ke kiʻi oxidation ma luna o ka mea e-welded. Pono nā ʻenehana wiliwili like ʻole e hoʻohana i ka pauka scaling ʻokoʻa. No ka wiliwili ʻana i nā mea uila e like me PCB, pono e hoʻohana ʻia ka rosin e like me ka pauka scaling e hōʻoia i ka hilinaʻi kuʻi.

4. Pono e wela ka mea i ka mahana kūpono

Inā haʻahaʻa loa ka wela wili, ʻaʻole hiki ke hana ʻia ka huila. A inā he kiʻekiʻe loa ka wela o ka welding, e noho ka welding flux i ke kūlana non-eutectic, e hōʻemi ana i ka maikaʻi o ka flux welding a i ka hihia maikaʻi loa, e hāʻule ka pad ma ka PCB.

5. ʻO ka welding e pono ai ka manawa kūpono

ʻO ka manawa welding ke ʻano o ka manawa i hoʻohana ʻia i ka hopena kemika a me ke kino i ke kaʻina hana. Ma hope o ka hoʻoholo ʻana i ka mahana welding, pono nā mea hoʻohana e hoʻoholo i ka manawa wili kūpono e pili ana i ke ʻano, ka maikaʻi a me nā hiʻohiʻona o nā mea e hoʻopili ʻia. Inā lōʻihi ka manawa welding, hiki ke hōʻino ʻia nā ʻāpana a i ʻole nā ʻāpana welded. ʻO ka mea maʻamau, ʻaʻole pono ka lōʻihi o kēlā me kēia wahi ma mua o 5 kekona i ka manawa.

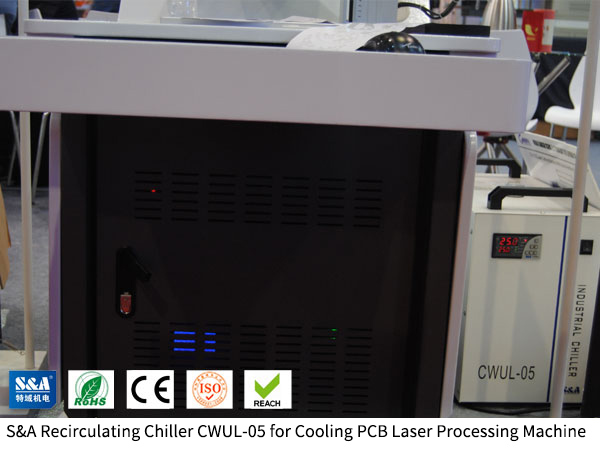

I mea e mālama ai i ka mīkini hoʻoheheʻe laser PCB i kona maikaʻi loa, pono e hoʻomaʻalili pono ʻia e kahi chiller ʻoihana. S&A Ua hoʻolaʻa ʻo Teyu i ka pahu hau ʻenehana no 19 mau makahiki a hiki iā ia ke hāʻawi i nā chillers ʻoihana no nā ʻano mīkini wili laser. Hōʻike ka recirculating chillers i ka maʻalahi o ka hoʻohana ʻana, ka mālama haʻahaʻa, ke ola lawelawe lōʻihi, ka hilinaʻi like ʻole. ʻO ka mana hoʻomaha mai 0.6KW a 30KW, hiki ke hoʻokō i nā pono hoʻomaha mai nā mea hoʻohana like ʻole. Inā ʻaʻole ʻoe maopopo i ke ʻano chiller recirculating e koho ai, e leka uila wale iā mākou marketing@teyu.com.cn