Njengoba sazi sonke, i-PCB “ibhuloho” lokuxhuma izingxenye zikagesi ngayinye futhi iyingxenye enkulu emikhiqizweni kagesi. Inezinhlelo zokusebenza ezihlukahlukene, ezihlanganisa ugesi wabathengi, ugesi wezimoto, ukuxhumana, imithi, iphrojekthi yezempi, i-aerospace nokunye. Namuhla, ama-electronics abathengi kanye ne-automobile electronics zithola ukuthuthuka okushesha kakhulu futhi kuba yizinkambu eziyinhloko zokufaka isicelo. Ngalesi sikhathi, ukushiselwa kwe-PCB kudonse ukunaka okukhulu okuvela kubakhiqizi be-PCB. Ngakho-ke, yiziphi izinhlobo ze-PCB ezingasebenza kuzo umshini wokushisela we-laser? Ake sibhekisise ngezansi.

1.Into idinga ukushiselwa

Kusho ukuthi ngaphansi kwezinga lokushisa elifanele, insimbi ezoncibilika kanye nethayela elihlanganisiwe kungahlangana ndawonye ukuze kube nekhwalithi enhle yekhwalithi ye-alloy. Akuzona zonke izinsimbi ezinokushisela okuhle. Ukuze kuthuthukiswe ukushiseleka kwensimbi, abasebenzisi bangenza i-tin-plating noma i-silver-plating ensimbi ukuvimbela i-oxidation yendawo yensimbi.

2.Into idinga ukuhlanzeka phezulu

Ukuze uhlanganise i-solder tin kanye nezinto ezizoncibilika, indawo engaphezulu yento idinga ukuhlanzeka. Ngisho nasezintweni ezinhle zokushisela, ifilimu ye-oxidation noma ibala lamafutha kungenzeka endaweni yento. Ngakho-ke, ukuze kuqinisekiswe ikhwalithi yokushisela, indawo engaphezulu kufanele ihlanzeke.

3.Sebenzisa impushana yokukala efanelekile

Inhloso ye-scaling powder ukukhipha ifilimu ye-oxidation entweni okumele ibe-welded. Amasu okushisela ahlukene kufanele asebenzise i-powder yokukala ehlukile. Ukuze uthole izinto zikagesi ezinembayo zokushisela njenge-PCB, i-rosin kufanele isetshenziswe njengempushana yokukala ukuze kuqinisekiswe ukwethembeka kokushisela.

4.Into idinga ukushiselwa ngezinga lokushisa elifanele

Uma izinga lokushisa lokushisela liphansi kakhulu, i-alloy ayikwazi ukwakhiwa. Futhi uma izinga lokushisa lokushisela liphezulu kakhulu, i-welding flux izohlala esimweni esingesona se-eutectic, esizonciphisa ikhwalithi ye-welding flux futhi esimweni esibi kakhulu, i-pad ku-PCB izokwehla.

5.I-welding idinga isikhathi esifanele

Isikhathi sokushisela sisho isikhathi esichithwa ekuphenduleni kwamakhemikhali nangokomzimba ohlelweni lokushisela. Ngemva kokunquma izinga lokushisa lokushisela, abasebenzisi kufanele banqume isikhathi esifanele sokushisela ngokusekelwe ekubunjweni, ikhwalithi kanye nezici zezinto ezizofakwa. Uma isikhathi sokushisela siside kakhulu, izingxenye noma izingxenye ezishiselwe kulula ukonakala. Ngokuvamile, indawo ngayinye akufanele ithathe ngaphezu kwamasekhondi angu-5 ngesikhathi.

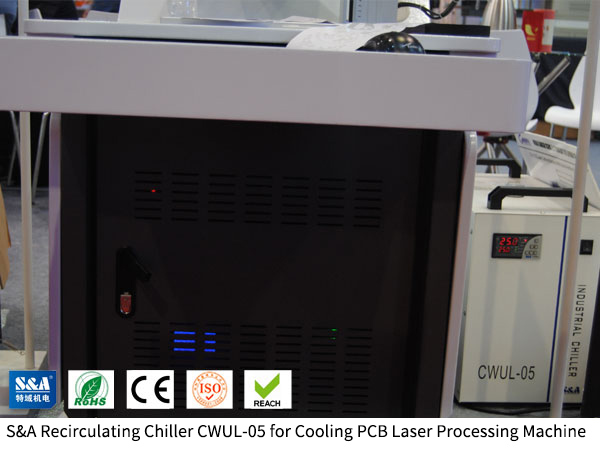

Ukuze ugcine umshini wokushisela we-laser we-PCB usezingeni eliphezulu, udinga ukupholiswa kahle ngumuntu opholile embonini. S&A I-Teyu isineminyaka engu-19 inikezela esiqandisini sezimboni futhi inganikeza ama-chiller ezimboni ngezinhlobo ezahlukene zemishini yokushisela i-laser. Ama-chiller ajikelezayo afaka ukusetshenziswa kalula, ukunakekelwa okuphansi, impilo ende yesevisi, ukwethembeka okungenakuqhathaniswa. Umthamo wokupholisa usukela ku-0.6KW kuye ku-30KW, ongahlangabezana nezidingo zokupholisa kubasebenzisi abahlukene. Uma ungenaso isiqiniseko sokuthi iyiphi imodi ye-chiller ongayikhetha, vele usithumele i-imeyili kuyo marketing@teyu.com.cn