![recirculating Laser ruwa chiller recirculating Laser ruwa chiller]()

Chip yana taka muhimmiyar rawa a cikin manyan masana'antu, kamar wayar hannu, kwamfuta, kayan aikin gida, na'urar GPS, da dai sauransu. Kuma babbar na'urar da ke yin guntu galibi masana'antun kasashen waje ne ke mamaye su.

Kadan aikace-aikace na semiconductor kayan

Stepper shine tsarin bayyanar abin rufe fuska. Ta amfani da tushen Laser don ƙaddamar da fim ɗin kariya ta fuskar wafer, za a samar da kewaye tare da aikin adana bayanai. Yawancin masu amfani suna amfani da Laser excimer wanda zai iya samar da zurfin Laser UV. Babban kuma babban mai kera Laser Cymer ya samu ta ASML. Kuma sabon stepper zai zama EUV stepper wanda zai iya fahimtar aiwatar da ƙasa da 10nm. Amma wannan dabarar har yanzu kamfanonin kasashen waje sun mamaye ta.

Amma ana sa ran kasar Sin a hankali za ta ci gaba da samun ci gaba wajen yin guntu, daga baya kuma za ta iya samar da kanta da yawan jama'a. Matsakaicin cikin gida kuma ana iya gani sannan kuma, buƙatun tushen madaidaicin Laser zai ƙaru.

Wani faffadan aikace-aikacen kayan aikin semiconductor shine masana'antar sel ta PV wacce ita ce kasuwa mafi girma mai tsabta mai tsabta tare da mafi kyawun yuwuwar a duniya. Za a iya raba Kwayoyin hasken rana zuwa sel silikon crystalline, baturin fim na bakin ciki da baturin fili na III-V. Daga cikin waɗannan, kristal silicon hasken rana cell yana da mafi fadi aikace-aikace. Kishiyar tushen Laser, PV cell shine na'urar da ke watsa haske zuwa wutar lantarki. Matsakaicin jujjuyawar hoto shine ma'auni don faɗin yadda ƙwayar PV take da kyau. Kayan aiki da fasaha na tsari a wannan yanki yana da matukar mahimmanci.

Dangane da yankan wafer silicon, an yi amfani da kayan aikin yankan gargajiya, amma tare da ƙarancin daidaito da ƙarancin inganci da ƙarancin amfanin ƙasa. Sabili da haka, yawancin ƙasashen Turai, Koriya ta Kudu, Amurka sun riga sun gabatar da fasaha mai mahimmanci na Laser dogon lokaci da suka wuce. Ga ƙasarmu, ƙarfin samar da ƙwayar PV ya kai rabin duniya. Kuma a cikin shekaru 4 da suka gabata, yayin da masana'antar PV ta ci gaba da haɓaka, ana amfani da fasahar sarrafa laser a hankali. A zamanin yau, fasahar Laser tana ba da gudummawa ga masana'antar PV ta hanyar yin yankan wafer, rubutun wafer, tsagi na batirin PERC.

Aikace-aikace na uku na semiconductor shine PCB, gami da FPCB. PCB, wanda shine maɓalli mai mahimmanci kuma tushen duk kayan lantarki, yana amfani da adadi mai yawa na kayan semiconductor. A cikin 'yan shekarun da suka gabata, yayin da daidaito da haɗin kai na PCB ya zama mafi girma kuma mafi girma, ƙananan da ƙananan PCB zasu fito. A lokacin, na'urar sarrafa na'urar gargajiya da na'urar sadarwa za ta yi wuyar daidaitawa, amma fasahar laser za ta ƙara yin amfani da ita.

Alamar Laser ita ce hanya mafi sauƙi akan PCB. A halin yanzu, mutane sukan yi amfani da Laser UV don yin alama a saman kayan. Laser hakowa, duk da haka, shine mafi yawan fasaha akan PCB. Hakowa Laser na iya kaiwa matakin micrometer kuma yana iya yin ƙaramin rami wanda wuƙan injina ta kasa yi. Bugu da kari, jan abu yankan da kafaffen Fusion waldi a kan PCB kuma iya daukar Laser dabara.

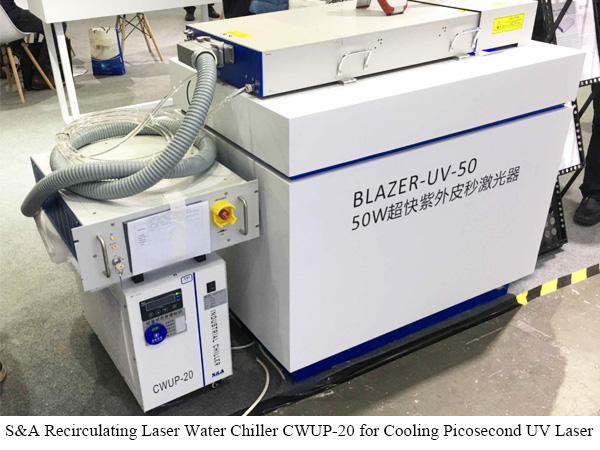

Yayin da Laser ya shiga zamanin micro-machining, S&A Teyu ya inganta ingantaccen iska mai sanyaya ruwa

Neman baya da Laser ci gaban a baya 'yan shekaru, Laser yana da fadi da aikace-aikace a karfe yankan da waldi. Amma ga madaidaicin micro-machining, yanayin shine ɗayan hanyar. Daya daga cikin dalilan shi ne cewa sarrafa karfe nau'in nau'in injin ne. Amma babban madaidaicin micro-machining na laser yana buƙatar babban matakin gyare-gyare kuma yana fuskantar ƙalubale kamar wahalar haɓaka wannan fasaha da yawancin lokacin da aka kashe. A zamanin yau, babban madaidaicin micro-machining na laser yana da hannu a cikin kayan lantarki na mabukaci kamar wayo mai wayo wanda allon OLED yakan yanke ta micro-machining.

A cikin shekaru 10 masu zuwa, semiconductor abu zai zama masana'antar fifiko. Mai yiwuwa sarrafa kayan Semiconductor na iya zama ƙwaƙƙwaran saurin haɓaka micro-machining Laser. Laser micro-machining galibi ana amfani da gajeriyar pulsed ko ultra-short pulsed Laser, wanda kuma aka sani da ultrafast Laser. Sabili da haka, tare da yanayin gida na kayan aikin semiconductor, buƙatar babban madaidaicin sarrafa laser zai karu.

Koyaya, babban na'urar laser ultrafast na'urar tana da matukar wahala kuma tana buƙatar sanye take da na'urar sarrafa zafin jiki daidai gwargwado.

Don saduwa da tsammanin kasuwa na na'urar laser mai mahimmanci na cikin gida, S&A Teyu ya haɓaka jerin CWUP masu sake zagayowar ruwan sanyi na Laser wanda kwanciyar hankalin zafinsa ya kai ± 0.1 ℃ kuma an tsara shi musamman don sanyaya laser ultrafast kamar Laser femtosecond, nanosecond Laser, picosecond Laser, da dai sauransu. https://www.teyuchiller.com/portable-water-chiller-cwup-20-for-ultrafast-laser-and-uv-laser_ul5

![recirculating Laser ruwa chiller recirculating Laser ruwa chiller]()