![recirculating laser mvura chiller recirculating laser mvura chiller]()

Chip inoita basa rakakosha mumaindasitiri epamusoro-soro, senge smart phone, komputa, midziyo yemumba, GPS mudziyo, etc. Uye musimboti mudziyo unogadzira iyo chip inowanzotongwa nevagadziri vekunze.

Zvishoma zvekushandisa zve semiconductor zvinhu

Stepper ndeye mask exposure system. Nekushandisa laser sosi yekuisa iyo yepamusoro inodzivirira firimu rewafer, dunhu richaumbwa nebasa rekuchengetedza data. Mazhinji ema steppers anotora excimer laser iyo inogona kuburitsa yakadzika UV laser beam. Iyo inotungamira uye yakakura excimer laser inogadzira Cymer yakawanikwa neASML. Uye iyo itsva stepper ingave EUV stepper iyo inogona kuona maitiro ari pazasi 10nm. Asi hunyanzvi uhu pari zvino huchiri kutungamirwa nemakambani ekunze.

Asi zvinotarisirwa kuti China iri kuita budiriro mukugadzira chip uye gare gare pakuziva kuzvigadzira uye kugadzira kwakawanda. Vatambi vepamba vanoonekwa zvakare uye panguva iyoyo, kudiwa kweiyo yakakwira chaiyo laser sosi kuchave kuchiwedzera.

Kumwe kushandiswa kwakakura kwezvinhu zve semiconductor ndeye PV cell indasitiri inova inokurumidza kukura yakachena simba musika ine yakanyanya kugona munyika. Solar maseru anogona kukamurwa kuita crystalline silicon solar cell, nhete-firimu bhatiri uye III-V bhatiri remusanganiswa. Pakati peizvi, iyo crystalline silicon solar cell ine yakanyanya kushandisa. Kupesana nelaser source, PV cell chishandiso chinoendesa mwenje kumagetsi. Photoelectric inoshandura chiyero ndiyo chiyero chekutaura kunaka kwePV cell. Zvinhu uye maitiro ekugadzirisa munzvimbo iyi akakosha.

Panyaya yekucheka silicon wafer, chinyakare chekucheka chishandiso chakashandiswa, asi nekushomeka kwakadzika uye kuderera kwekuita uye goho rakaderera. Naizvozvo, nyika zhinji dzeEurope, South Korea, United States dzakatounza yakakwirira precision laser maitiro kare kare. Kunyika yedu, kugona kwedu kwekugadzira kwePV cell kwasvika hafu yenyika. Uye mumakore mana apfuura, sezvo indasitiri yePV iri kuramba ichikura, nzira yekugadzira laser yakashandiswa zvishoma nezvishoma. Mazuva ano, nzira yelaser iri kubatsira kuindasitiri yePV nekuita wafer yekucheka, wafer kunyora, grooving yePERC bhatiri.

Yechitatu yekushandisa semiconductor ndeye PCB, kusanganisira FPCB. PCB, inova chikamu chakakosha uye hwaro hwezvese zvemagetsi, inoshandisa yakawanda semiconductor zvinhu. Mumakore mashoma apfuura, sezvo iko kurongeka uye kubatanidzwa kwePCB kunowedzera nekukwirira, diki uye diki PCB ichabuda. Pakazosvika nguva iyoyo, chinyakare kugadzirisa uye kusangana nekugadzirisa mudziyo kuchave kwakaoma kuchinjika, asi laser tekinoroji inozowedzera kushandiswa.

Laser yekumaka ndiyo nzira yakapusa paPCB. Parizvino, vanhu vanowanzo shandisa UV laser kuita kumaka pamusoro pezvinhu. Laser drilling, zvisinei, ndiyo yakajairika nzira paPCB. Laser drilling inogona kusvika micrometer level uye inogona kuita buri diki diki diki diki rikatadza kuitwa nebanga remuchina. Pamusoro pezvo, kucheka zvinhu zvemhangura uye yakagadziriswa fusion welding paPCB inogona zvakare kutora laser tekinoroji.

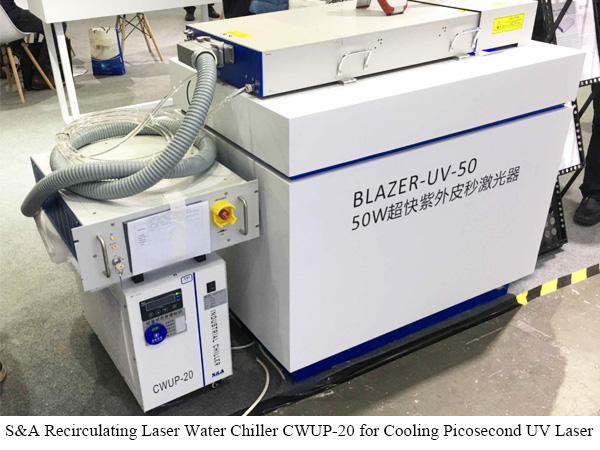

Sezvo laser ichipinda micro-machining era, S&A Teyu yakasimudzira yekupedzisira-chaiyo mhepo inotonhorera mvura inotonhorera.

Tichitarisa kumashure kukura kwelaser mumakore mashoma apfuura, laser ine yakafara maapplication mukucheka simbi uye welding. Asi kune yakakwirira chaiyo micro-machining, mamiriro acho ndeimwe nzira yakatenderedza. Chimwe chechikonzero ndechekuti kugadzira simbi imhando yekukasharara machining. Asi yakakwirira chaiyo laser micro-machining inoda yakakwira mwero wekugadzirisa uye inotarisana nematambudziko sekuoma kwekugadzira iyi tekiniki uye yakawanda nguva inoshandiswa. Mazuva ano, high precision laser micro-machining inonyanya kubatanidzwa mumagetsi evatengi sefoni smart iyo OLED skrini inowanzochekwa nelaser micro-machining.

Mumakore gumi ari kuuya, semiconductor zvinhu zvichave zvakakosha indasitiri. Semiconductor material processing inogona kunge iri kukurudzira kwekukurumidza kukura kwelaser micro-machining. Laser micro-machining inonyanya kushandiswa pfupi-pulsed kana Ultra-pfupi pulsed laser, inozivikanwawo se Ultrafast laser. Naizvozvo, nemaitiro ekubatisa semiconductor zvinhu, kudiwa kweiyo yakakwirira chaiyo laser kugadzirisa kuchawedzera.

Nekudaro, yakanyanya kurongeka ultrafast laser mudziyo inonyatso kudiwa uye inoda kuve yakashongedzerwa yakaenzana yakakwirira chaiyo tembiricha yekudzora mudziyo.

Kuti isangane nemusika tarisiro yemumba yakakwira chaiyo laser mudziyo, S&A Teyu yakasimudzira CWUP yakatevedzana inotenderedza laser mvura chiller ine tembiricha yakadzikama inosvika ± 0.1 ℃ uye yakanyatsogadzirirwa kutonhorera ekupedzisira lasers senge femtosecond laser, nanosecond laser, piccosecond mvura inoteedzana paCWUP ruzivo rwakawanda pamusoro peCWU. https://www.teyuchiller.com/portable-water-chiller-cwup-20-for-ultrafast-laser-and-uv-laser_ul5

![recirculating laser mvura chiller recirculating laser mvura chiller]()