![qaboojiyaha biyaha laysarka ee dib u wareega qaboojiyaha biyaha laysarka ee dib u wareega]()

Chip waxa uu door muhiim ah ka ciyaaraa wershadaha ugu sareeya, sida talefoonada casriga ah, kombayutarka, qalabka guriga, qalabka GPS-ka, iwm.

Codsiyo yar oo ah qalabka semiconductor

Stepper waa habka soo-gaadhista waji-xidhka. Adigoo isticmaalaya isha laysarka si loo dhajiyo filimka ilaalinta dusha sare ee waferka, wareegga waxaa la samayn doonaa iyada oo la kaashanaysa kaydinta xogta. Inta badan steppers-yada waxay qaataan laser excimer kaas oo soo saari kara shucaaca laser UV qoto dheer. Hormuudka iyo soo saaraha laser-ka weyn ee Cymer waxaa la wareegay ASML. Talaabada cusubna waxay noqon doontaa talaabaha EUV kaas oo xaqiijin kara habka ka hooseeya 10nm. Laakiin farsamadan ayaa hadda waxaa gacanta ku haya shirkadaha ajnabiga ah.

Laakiin waxaa la filayaa in Shiinuhu uu si tartiib tartiib ah u horumariyo samaynta chips-ka oo hadhow uu xaqiijiyo wax-soo-saarka iyo wax-soo-saarka tirada badan. Talaabooyin gudaha ah ayaa sidoo kale la arki karaa ka dibna, baahida isha laysarka saxda ah ayaa sii kordheysa.

Codsiga kale ee ballaaran ee agabka semiconductor waa warshadaha unugyada PV kaas oo ah suuqa tamarta nadiifka ah ee ugu dhaqsaha badan u koraya oo leh awooda ugu wanaagsan adduunka. Unugyada qoraxda waxa loo qaybin karaa unug cadceedda silikon crystalline, batari filim khafiif ah iyo batari ka kooban III-V. Kuwaas waxaa ka mid ah, unugga cadceedda silikoon ee crystalline ayaa leh codsiga ugu ballaaran. Ka soo horjeeda isha laysarka, unugga PV waa aalad u gudbisa iftiin koronto. Heerka beddelka korontadu waa halbeegga lagu sheegayo sida unugga PV u wanaagsan yahay. Qalabka iyo farsamada habraaca ee aaggan ayaa aad muhiim u ah.

Marka la eego jarista wafer silikoon, qalab goynta dhaqameed ayaa la isticmaalay, laakiin leh saxnaanta hoose iyo hufnaanta hoose iyo waxsoosaarka hooseeya. Sidaa darteed, dalal badan oo Yurub ah, Kuuriyada Koonfureed, Mareykanka ayaa horeyba u soo bandhigay farsamo laser sax ah oo sax ah wakhti dheer ka hor. Waddankeena, awoodda wax-soo-saarka unugyada PV waxay gaartay kala bar adduunka. Iyo 4tii sano ee la soo dhaafay, sida warshadaha PV ay sii wadeen inay koraan, farsamada farsamaynta laser ayaa si tartiib tartiib ah loo isticmaalay. Maalmahan, farsamada laysarka ayaa wax ku biirinaysa warshadaha PV iyada oo la samaynayo jarista wafer, qorida wafer, gooynta batteriga PERC.

Codsiga saddexaad ee semiconductor waa PCB, oo ay ku jiraan FPCB. PCB, oo ah qaybta muhiimka ah iyo saldhigga dhammaan qalabka elektaroonigga ah, waxay isticmaashaa xaddi badan oo ah qalabka semiconductor. Dhowrkii sano ee la soo dhaafay, marka saxnaanta iyo is dhexgalka PCB ay sare u kacdo, PCB-ga yar iyo midka yar ayaa soo bixi doona. Markaas, qalabaynta hab-dhaqameedka iyo xidhiidhka xidhiidhka way adkaan doontaa in la qabsado, laakiin farsamada laysarka ayaa noqon doonta mid aad iyo aad u badan oo la isticmaalo.

Calaamadaynta laser waa farsamada ugu fudud ee PCB. Waqtigan xaadirka ah, dadku waxay inta badan isticmaalaan UV laser si ay u sameeyaan calaamadaynta dusha sare ee alaabta. Laysarka qodista, si kastaba ha ahaatee, waa farsamada ugu badan ee PCB. Qodista leeserku waxay gaari kartaa heerka mikrometer-ka waxayna sameyn kartaa dalool aad u yar oo mindida farsamadu aysan sameyn karin. Intaa waxaa dheer, goynta walxaha naxaasta iyo alxanka fiyuuska go'an ee PCB waxay sidoo kale qaadan kartaa farsamada laysarka.

Sida laysarka uu galo xilliga mishiinada-yar, S&A Teyu waxa uu kor u qaaday qaboojiyaha hawo aadka u saxan

Dib u milicsiga horumarka laysarka ee dhowrkii sano ee la soo dhaafay, laser wuxuu leeyahay codsiyada ballaaran ee goynta birta iyo alxanka. Laakiin mashiinnada-yar ee saxda ah ee saxda ah, xaaladdu waa si kale. Mid ka mid ah sababaha ayaa ah in farsamaynta birta ay tahay nooc ka mid ah mashiinnada qallafsan. Laakin saxnaanta sare ee laser micro-machining waxay u baahan tahay habayn heer sare ah waxayna wajaheysaa caqabado ay ka mid yihiin inay adag tahay horumarinta farsamadan iyo waqti badan oo lagu qaatay. Maalmahan, mishiinnada yar-yar ee leysarka saxda ah ayaa inta badan ku lug leh macaamiisha elektiroonigga ah sida taleefoonka smart oo shaashada OLED ay inta badan goyso laysarka micro-machining.

10-ka sano ee soo socda, walxaha semiconductor waxay noqon doonaan warshadaha mudnaanta leh. Habaynta walxaha semiconductor waxay u badan tahay inay noqoto kicinta horumarka degdega ah ee mishiinada yar yar ee laysarka. Laser-machining-ga yar ee inta badan la isticmaalo pulsed-gaaban ama ultra-gaaban laser, oo sidoo kale loo yaqaano ultrafast laser. Sidaa darteed, iyada oo la raacayo isbeddelka guriga ee walxaha semiconductor, baahida farsamaynta laser saxda ah ayaa kordhin doonta.

Si kastaba ha noqotee, aaladda saxda ah ee saxda ah ee ultrafast laser waa mid aad u baahan oo waxay u baahan tahay in lagu qalabeeyo aaladda xakamaynta heerkulka saxda ah si siman.

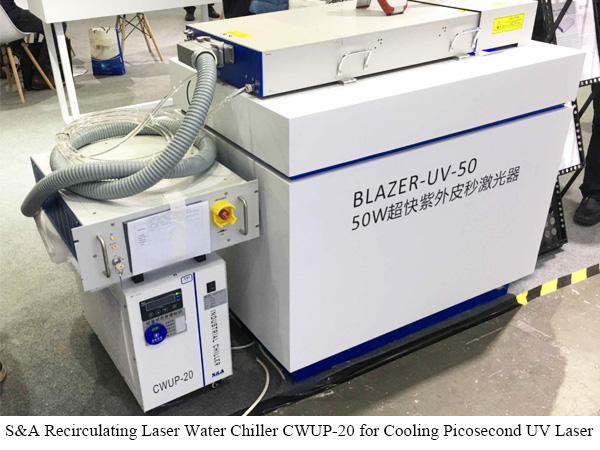

Si loo daboolo rajada suuqa ee qalabka leysarka saxda ah ee gudaha, S&A Teyu wuxuu kor u qaaday taxanaha CWUP ee dib u wareejinaya qaboojiyaha biyaha laysarka kaas oo heerkulkiisu gaaro ± 0.1 ℃ waxaana si gaar ah loogu talagalay qaboojinta lasers ultrafast sida laser femtosecond, laser nanosecond, laser picosecond, iwm. https://www.teyuchiller.com/portable-water-chiller-cwup-20-for-ultrafast-laser-and-uv-laser_ul5

![qaboojiyaha biyaha laysarka ee dib u wareega qaboojiyaha biyaha laysarka ee dib u wareega]()