![recirculating laser amanzi chiller recirculating laser amanzi chiller]()

I-Chip idlala indima ebalulekileyo kumashishini aphezulu, njengefowuni ehlakaniphile, ikhompyutha, izixhobo zasekhaya, isixhobo seGPS, njl.

Ukusetyenziswa okumbalwa kwemathiriyeli ye-semiconductor

I-Stepper yinkqubo yokuvezwa kwemaski. Ngokusebenzisa umthombo we-laser ukubethela ifilimu ekhuselayo yomhlaba we-wafer, isekethe iya kwenziwa kunye nomsebenzi wokugcina idatha. Uninzi lwamanyathelo athatha i-laser ye-excimer enokuvelisa i-UV laser beam enzulu. Umvelisi ophambili kunye nomkhulu we-laser excimer uCymer wafunyanwa yi-ASML. Kwaye i-stepper entsha iya kuba yi-EUV stepper enokuqonda inkqubo engaphantsi kwe-10nm. Kodwa obu buchule ngoku busalawulwa ziinkampani zangaphandle.

Kodwa kulindeleke ukuba i-China ngokuthe ngcembe iqhubele phambili ekwenzeni i-chip kwaye kamva iqonde ukuvelisa ngokwayo kunye nemveliso enkulu. Izitepsi zasekhaya zikwabonwa kwangaphambili kwaye ngelo xesha, imfuno yomthombo welaser echanekileyo iya kunyuka.

Olunye usetyenziso olubanzi lwemathiriyeli ye-semiconductor lishishini leeseli ze-PV elona likhula ngokukhawuleza intengiso yamandla acocekileyo nenamandla emhlabeni. Iiseli zelanga zinokwahlulwa zibe yikristale yesilicon yeseli yelanga, ibhetri yefilim encinci kunye ne-III-V ibhetri edibeneyo. Phakathi kwezi, i-crystalline silicon iseli yelanga inesona sicelo sibanzi. Ngokuchasene nomthombo we-laser, i-PV cell sisixhobo esihambisa ukukhanya kumbane. Ireyithi yokuguqula i-Photoelectric ngumgangatho wokuxela ukuba ilungile kangakanani iseli yePV. Imathiriyeli kunye nobuchule benkqubo kule ndawo bubaluleke kakhulu.

Ngokuphathelele ukusika i-silicon wafer, isixhobo sokusika sendabuko sisetyenzisiwe, kodwa ngokuchaneka okuphantsi kunye nokusebenza okuphantsi kunye nesivuno esiphantsi. Ke ngoko, amazwe amaninzi aseYurophu, uMzantsi Korea, iUnited States sele yazisa ubuchule belaser obuchanekileyo kwakudala. Kwilizwe lethu, amandla ethu okuvelisa i-PV cell afikelele kwisiqingatha sehlabathi. Kwaye kwiminyaka emi-4 edlulileyo, njengoko ishishini le-PV liye laqhubeka likhula, ubuchule bokucutshungulwa kwe-laser busetyenziswe ngokuthe ngcembe. Kule mihla, ubuchule belaser bunegalelo kwishishini le-PV ngokwenza ukusika i-wafer, i-wafer scribing, i-grooving yebhetri ye-PERC.

Isicelo sesithathu se-semiconductor yi-PCB, kuquka ne-FPCB. I-PCB, eyona nto iphambili kunye nesiseko sayo yonke i-elektroniki, isebenzisa isixa esikhulu semathiriyeli ye-semiconductor. Kwiminyaka embalwa edlulileyo, njengoko ukuchaneka kunye nokudityaniswa kwe-PCB kuya kuba phezulu nangaphezulu, i-PCB encinci kunye nencinci iya kuphuma. Ngelo xesha, ukusetyenzwa kwemveli kunye nesixhobo soqhagamshelwano kuya kuba nzima ukuziqhelanisa, kodwa ubuchule belaser buya kusetyenziswa ngakumbi nangakumbi.

Ukumakishwa kweLaser yeyona ndlela ilula kwiPCB. Okwangoku, abantu bahlala besebenzisa i-laser ye-UV ukwenza ukumakisha kumphezulu wezinto. Ukugrumba iLaser, nangona kunjalo, yeyona ndlela ixhaphakileyo kwiPCB. Ukombiwa kweLaser kunokufikelela kwinqanaba lemicrometer kwaye kungenza umngxuma omncinci kakhulu ongenakukwazi ukuwenza imela ngoomatshini. Ukongeza, ukusika izinto zobhedu kunye ne-fusion esisigxina ye-PCB inokusebenzisa ubuchule be-laser.

Njengoko i-laser ingena kwi-micro-machining era, S&A iTeyu yakhuthaza i-ultra-chanisekile umoya opholileyo wokupholisa amanzi

Ukujonga emva kophuhliso lwelaser kule minyaka imbalwa idlulileyo, i-laser inezicelo ezibanzi zokusika isinyithi kunye ne-welding. Kodwa ngokuchaneka okuphezulu kwe-micro-machining, imeko yenye indlela. Esinye sezizathu kukuba ukucutshungulwa kwesinyithi luhlobo lomatshini orhabaxa. Kodwa ukuchaneka okuphezulu kwe-laser micro-machining kufuna umgangatho ophezulu wokwenza ngokwezifiso kwaye ijongana nemiceli mngeni efana nobunzima bokuphuhlisa obu buchule kunye nexesha elininzi elichithiweyo. Kule mihla, ukuchaneka okuphezulu kwe-laser micro-machining kubandakanyeka ikakhulu kubathengi be-elektroniki njengefowuni ehlakaniphile enesikrini se-OLED esihlala sisikwa yi-laser micro-machining.

Kwiminyaka eli-10 ezayo, imathiriyeli ye-semiconductor iya kuba lishishini eliphambili. Ukusetyenzwa kwemathiriyeli yeSemiconductor mhlawumbi kunokuba luvuselelo lophuhliso olukhawulezayo lwelaser micro-machining. I-Laser micro-machining isetyenziswa ikakhulu i-short-pulsed okanye i-ultra-short pulsed laser, eyaziwa ngokuba yi-ultrafast laser. Ke ngoko, ngomkhwa wokwenziwa kwasekhaya kwemathiriyeli ye-semiconductor, imfuno yokuchaneka okuphezulu kwelaser iya kunyuka.

Nangona kunjalo, isixhobo se-laser esichaneke kakhulu sifunwa kakhulu kwaye kufuneka sixhotyiswe ngesixhobo sokulawula ubushushu obuphezulu.

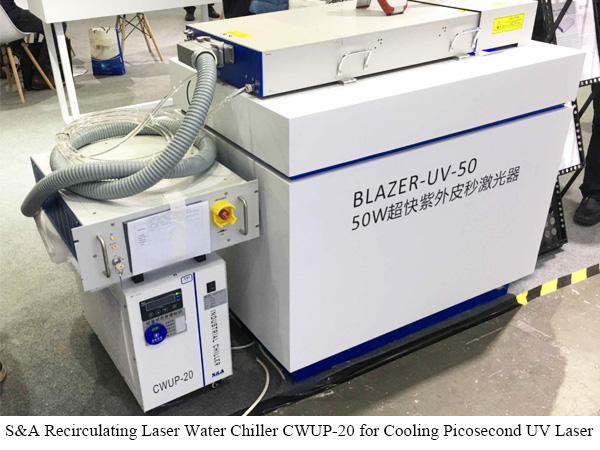

Ukuhlangabezana nolindelo lwentengiso yesixhobo se-laser esichanekileyo sasekhaya, S&A I-Teyu ikhuthaze uthotho lwe-CWUP olujikelezayo i-laser water chiller ezizinzo lobushushu lifikelela ku-± 0.1 ℃ kwaye yenzelwe ngokukodwa ukupholisa ii-laser ze-ultrafast njenge-laser ye-femtosecond, i-laser ye-nanosecond, i-piccosecond i-laser ye-picosecond ngolwazi olungakumbi malunga ne-CWUP yolwazi lwe-laser yamanzi, njl. https://www.teyuchiller.com/portable-water-chiller-cwup-20-for-ultrafast-laser-and-uv-laser_ul5

![recirculating laser amanzi chiller recirculating laser amanzi chiller]()