![recirculating laser amanzi chiller recirculating laser amanzi chiller]()

I-Chip idlala indima ebalulekile ezimbonini ezisezingeni eliphezulu, njengefoni ehlakaniphile, ikhompuyutha, izinto zikagesi zasendlini, idivayisi ye-GPS, njll. Futhi idivayisi eyinhloko eyenza i-chip ngokuvamile ilawulwa abakhiqizi bangaphandle.

Izicelo ezimbalwa zezinto ze-semiconductor

I-Stepper iyisistimu yokuvezwa kwemaski. Ngokusebenzisa umthombo we-laser ukuze unamathisele ifilimu yokuvikela engaphezulu ye-wafer, isekethe izokwakhiwa nomsebenzi wokugcina idatha. Izitebhisi eziningi zisebenzisa i-excimer laser engakhiqiza ugongolo olujulile lwe-UV laser. Umkhiqizi we-laser excimer ohamba phambili nomkhulu uCymer watholwa yi-ASML. Futhi i-stepper entsha izoba yi-EUV stepper engakwazi ukubona inqubo engaphansi kwe-10nm. Kodwa le ndlela manje isaphethwe yizinkampani zakwamanye amazwe.

Kodwa kulindeleke ukuthi i-China kancane kancane iphumelele ekwenzeni ama-chip futhi kamuva ibone ukuzikhiqiza nokukhiqiza ngobuningi. Izitebhisi zasekhaya nazo ziyabonakala futhi ngaleso sikhathi, isidingo somthombo we-laser onembayo sizokhula.

Okunye ukusetshenziswa okubanzi kwezinto zokwakha ze-semiconductor imboni ye-PV cell okuyimakethe yamandla ahlanzekile ekhula ngokushesha enamandla amakhulu emhlabeni. Amaseli elanga angahlukaniswa abe yi-crystalline silicon solar cell, ibhethri lefilimu elincanyana kanye nebhethri elihlanganisiwe le-III-V. Phakathi kwalokhu, i-crystalline silicon solar cell inomsebenzi obanzi kakhulu. Ngokuphambene nomthombo we-laser, i-PV cell iyithuluzi elidlulisela ukukhanya kugesi. Izinga lokuguqula i-Photoelectric liyindinganiso yokusho ukuthi i-PV cell yinhle kangakanani. Impahla kanye namasu enqubo kule ndawo ibaluleke kakhulu.

Mayelana nokusika i-silicon wafer, ithuluzi lokusika lendabuko lasetshenziswa, kodwa ngokunemba okuphansi nokusebenza kahle okuphansi kanye nesivuno esincane. Ngakho-ke, amazwe amaningi ase-Europe, iSouth Korea, i-United States asevele ethule inqubo ye-laser enembayo esikhathini eside esidlule. Ezweni lethu, amandla ethu okukhiqiza amaseli e-PV afinyelele engxenyeni yomhlaba. Futhi eminyakeni engu-4 edlule, njengoba imboni ye-PV iqhubeka nokukhula, inqubo yokucubungula i-laser iye yasetshenziswa kancane kancane. Namuhla, indlela ye-laser inikela embonini ye-PV ngokwenza i-wafer cutting, i-wafer scribing, i-grooving yebhethri ye-PERC.

Isicelo sesithathu se-semiconductor yi-PCB, kuhlanganise ne-FPCB. I-PCB, okuyingxenye esemqoka kanye nesisekelo sazo zonke izinto zikagesi, isebenzisa inani elikhulu lezinto zokwakha ze-semiconductor. Eminyakeni embalwa edlule, njengoba ukunemba nokuhlanganiswa kwe-PCB kuya phezulu kuya phezulu, i-PCB encane nencane izophuma. Ngaleso sikhathi, ukucubungula kwendabuko kanye nedivayisi yokucubungula othintana naye kuzoba nzima ukuzivumelanisa nezimo, kodwa indlela ye-laser izosetshenziswa kakhulu.

Ukumaka nge-laser kuyindlela elula ku-PCB. Okwamanje, abantu bavame ukusebenzisa i-UV laser ukwenza ukumaka ebusweni bezinto. I-Laser drilling, nokho, iyindlela ejwayelekile kakhulu ku-PCB. Ukubhola nge-laser kungafinyelela izinga le-micrometer futhi kungenza imbobo encane kakhulu ummese womshini obungakwazi ukuwenza. Ngaphezu kwalokho, ukusika impahla yethusi kanye ne-fusion welding engaguquki ku-PCB nakho kungasebenzisa inqubo ye-laser.

Njengoba i-laser ingena enkathini yomshini omncane, S&A I-Teyu yakhuthaza isibandisi samanzi esinembe kakhulu somoya

Uma sibheka emuva ekuthuthukisweni kwe-laser eminyakeni embalwa edlule, i-laser inezinhlelo ezibanzi zokusika nokushisela insimbi. Kepha ngokunemba okuphezulu kwe-micro-machining, isimo singenye indlela. Esinye sezizathu ukuthi ukucutshungulwa kwensimbi kuwuhlobo lomshini onzima. Kodwa ukunemba okuphezulu kwe-laser micro-machining kudinga izinga eliphezulu lokwenza ngendlela oyifisayo futhi kubhekana nezinselelo ezinjengobunzima bokuthuthukisa le ndlela kanye nesikhathi esiningi esichithiwe. Ezinsukwini zanamuhla, ukunemba okuphezulu kwe-laser micro-machining kuhileleke kakhulu kuma-electronics abathengi njengocingo oluhlakaniphile oluvamise ukusikwa nge-laser micro-machining.

Eminyakeni eyi-10 ezayo, impahla ye-semiconductor izoba imboni ebaluleke kakhulu. Ukucubungula impahla ye-semiconductor kungase kube isikhuthazo sokuthuthuka okusheshayo kwe-laser micro-machining. I-laser micro-machining isetshenziswa kakhulu i-short-pulsed or ultra-short pulsed laser, eyaziwa nangokuthi i-ultrafast laser. Ngakho-ke, ngomkhuba wokwenziwa kwasekhaya kwempahla ye-semiconductor, isidingo sokucutshungulwa kwe-laser enembayo sizokhula.

Nokho, idivayisi ye-laser enembayo ephezulu idinga kakhulu futhi idinga ukuhlonyiswa ngedivayisi yokulawula izinga lokushisa enembayo ephezulu ngokulinganayo.

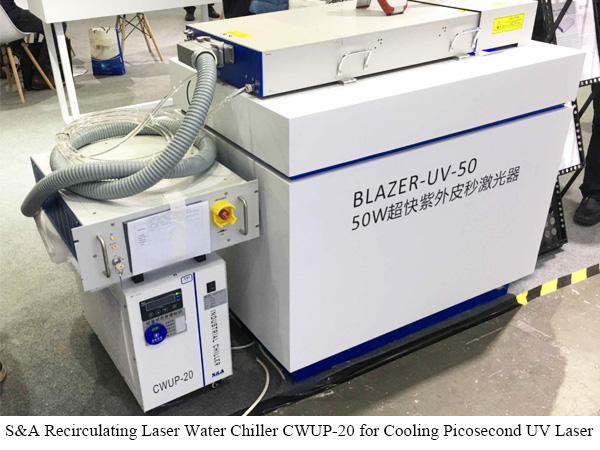

Ukuze kuhlangatshezwane nokulindelwe emakethe kwedivayisi ye-laser enembayo yasekhaya, S&A I-Teyu iphromothe uchungechunge lwe-CWUP olujikeleza kabusha i-laser water chiller okuzinze kwayo kwezinga lokushisa kufinyelela ku-±0.1℃ futhi yakhelwe ngokukhethekile ukupholisa ama-laser asheshayo afana ne-femtosecond laser, i-nanosecond laser, i-piccosecond leser yochungechunge ku-CW UP ulwazi olwengeziwe mayelana neyunithi ye-chiller. https://www.teyuchiller.com/portable-water-chiller-cwup-20-for-ultrafast-laser-and-uv-laser_ul5

![recirculating laser amanzi chiller recirculating laser amanzi chiller]()