Kuwongolera kutentha ndikofunikira pakupanga semiconductor kuti mupewe kupsinjika kwa kutentha, kuwongolera kukhazikika kwadongosolo, komanso kupititsa patsogolo magwiridwe antchito a chip. Zozizira bwino kwambiri zimathandizira kuchepetsa zolakwika monga ming'alu ndi delamination, kuonetsetsa kuti doping ikufanana, komanso kusunga makulidwe a oxide wosasinthasintha - zinthu zofunika kwambiri pakulimbikitsa zokolola ndi kudalirika.

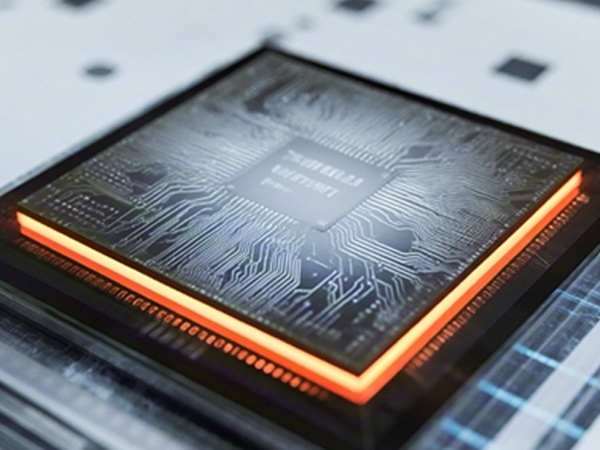

Chifukwa Chiyani Kuwongolera Kutentha Ndikofunikira Pakupanga Ma Semiconductor?

Pakupanga ma semiconductor, kuwongolera kutentha kolondola kumachita gawo lofunikira pakuwonetsetsa kuti chip chili chabwino, magwiridwe antchito, ndi zokolola. Ngakhale kusinthasintha pang'ono kwa kutentha kumatha kubweretsa kusintha kwakukulu pamachitidwe azinthu ndikukonza zotuluka, zomwe zitha kubweretsa kuwonongeka kapena kuwonongeka kwa zida.

Zotsatira za Kupsinjika kwa Matenthedwe

Zipangizo za semiconductor zimakhala ndi zigawo zingapo zazinthu zokhala ndi ma coefficients osiyanasiyana a kukula kwamafuta (CTE). Mwachitsanzo, zowotcha za silicon, zolumikizira zitsulo, ndi zigawo za dielectric zimakula kapena kukhazikika pamitengo yosiyana pakuwotcha kapena kuziziritsa mwachangu. Kusagwirizana uku kungayambitse kupsinjika kwamafuta, kumabweretsa zovuta zazikulu zopanga monga:

* Ming'alu: Mng'alu zam'mwamba kapena zamkati zamakina amatha kusokoneza kukhulupirika kwamakina ndikupangitsa kuti chipangizocho chilephereke.

* Delamination: Makanema owonda, monga zitsulo kapena dielectric layers, amatha kupatukana, kufooketsa mphamvu yamagetsi ya chip komanso kudalirika kwanthawi yayitali.

* Kusinthika kwamawonekedwe: Zopangira zida zimatha kupindika chifukwa cha kupsinjika, zomwe zimayambitsa mavuto amagetsi monga kutayikira kapena mabwalo afupi.

Udindo wa High-Precision Temperature Control

Makina apamwamba owongolera kutentha ngati ma TEYU mafakitale otenthetsera amapangidwa kuti azisunga kutentha mwatsatanetsatane mwapadera. Mwachitsanzo, TEYU's ultrafast laser chiller imapereka kuwongolera mpaka ± 0.08 ° C, kuwonetsetsa kukhazikika kwa zida za semiconductor zofunika kwambiri, kuphatikiza ma etchers, makina oyikapo, ndi zoyika ma ion.

Ubwino Wozizira Kwambiri mu Semiconductor Processes

1. Zimalepheretsa Kupsinjika kwa Kutentha Kwambiri: Mwa kusunga kuzizira kofanana, zozizira zimachepetsa zotsatira za CTE kusagwirizana pakati pa zipangizo zosiyanasiyana, kuchepetsa bwino chiopsezo cha ming'alu ndi delamination panthawi yotentha njinga.

2. Kumawonjezera Doping Uniformity: Pakuyika kwa ion ndi kulowetsedwa kotsatira, kutentha kosasunthika kumatsimikizira kutsegulidwa kwa dopant mosalekeza kudutsa mphika, kupititsa patsogolo ntchito ya chip ndi kudalirika.

3. Kumawonjezera Kusasinthika kwa Oxide Layer: Kuwongolera molondola kwa kutentha kumathandiza kuthetsa matenthedwe apakati-pakatikati pa nthawi ya okosijeni, kuonetsetsa kuti makulidwe a chipata cha oxide oxide, chofunikira kwambiri pamayendedwe osinthika a transistor.

Mapeto

Kuwongolera kutentha ndikofunikira pakupanga semiconductor. Ndi kasamalidwe kolondola kwambiri kwa kutentha, opanga amatha kuchepetsa zolakwika zomwe zimadza chifukwa cha kupsinjika kwamafuta, kuwongolera kufanana kwa doping ndi ma oxidation, ndipo pamapeto pake amapeza zokolola zapamwamba za chip ndikuchita bwino kwa chipangizocho.

Tabwera chifukwa cha inu mukadzatifuna.

Chonde lembani fomu yolumikizana nafe, ndipo tidzakhala okondwa kukuthandizani.