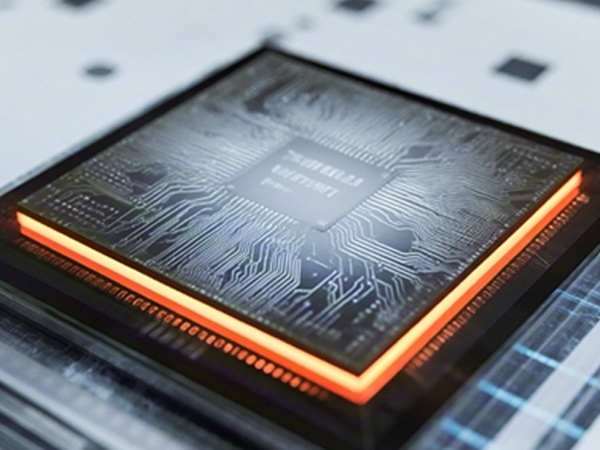

Njikwa okpomọkụ nke ọma dị mkpa n'ichepụta semiconductor iji gbochie nrụgide okpomọkụ, melite nkwụsi ike usoro, na ịkwalite ịrụ ọrụ mgbawa. Chillers dị elu na-enyere aka belata ntụpọ dị ka mgbawa na delamination, hụ na doping edo edo, ma na-edobe oke oyi akwa oxide na-agbanwe agbanwe - isi ihe na-akwalite mkpụrụ na ntụkwasị obi.

Kedu ihe kpatara njikwa okpomọkụ ji dị oke egwu na nrụpụta Semiconductor?

N'ichepụta semiconductor, njikwa okpomọkụ ziri ezi na-arụ ọrụ dị mkpa n'ịhụ na mgbawa, arụmọrụ, na mmepụta mmepụta. Ọbụna obere mgbanwe okpomọkụ nwere ike ime ka mgbanwe dị ukwuu na omume ihe yana nsonaazụ nhazi, nwere ike ibute ntụpọ ma ọ bụ ọdịda ngwaọrụ.

Mmetụta nke nrụgide okpomọkụ

Ngwa semiconductor nwere ọtụtụ ihe dị iche iche nwere ọnụọgụ dị iche iche nke mgbasawanye thermal (CTE). Ọmụmaatụ, silicon wafers, metal interconnects, na dielectric n'ígwé na-agbasa ma ọ bụ nkwekọrịta n'ọnụọgụ dị iche iche n'oge kpo oku ngwa ngwa ma ọ bụ jụrụ oyi. Nkwekọrịta a nwere ike ịmepụta nrụgide okpomọkụ, na-eduga ná nsogbu nrụpụta dị njọ dị ka:

* Mgbawa: elu ma ọ bụ mgbawa dị n'ime wafer nwere ike imebi iguzosi ike n'ezi ihe ma bute ọdịda ngwaọrụ.

* Delamination: Ihe nkiri dị gịrịgịrị, dị ka igwe ma ọ bụ akwa dielectric, nwere ike kewapụ, na-ebelata arụmọrụ ọkụ nke mgbawa na ntụkwasị obi ogologo oge.

* Nrụ arụ: Akụkụ ngwaọrụ nwere ike ịgbawa n'ihi nrụgide, na-ebute nsogbu eletrik dị ka ntapu ma ọ bụ sekit dị mkpụmkpụ.

Ọrụ nke njikwa okpomọkụ dị elu nke ọma

Sistemụ njikwa okpomọkụ dị elu dị ka TEYU ụlọ ọrụ chillers ka emebere iji kwado nkwụsi ike ọnọdụ okpomọkụ yana nkenke pụrụ iche. Dịka ọmụmaatụ, TEYU's ultrafast laser chiller na-enye njikwa njikwa ruru ± 0.08°C, na-ahụ nkwụsi ike nke usoro maka akụrụngwa semiconductor dị oke mkpa, gụnyere etcher, sistemu ntinye na ntinye ion.

Uru nke ịdị jụụ nke ọma na usoro Semiconductor

1. Na-egbochi nrụgide nrụgide okpomọkụ: Site n'ịkwado oyi oyi, chillers na-ebelata mmetụta nke CTE na-adaba n'etiti ihe dị iche iche, na-ebelata ihe ize ndụ nke cracks na delamination n'oge ịgba ígwè ọkụ.

2. Na-eme ka ịdị n'otu doping dịkwuo mma: Na ntinye ion na ntinye na-esote, ọnọdụ okpomọkụ kwụsiri ike na-eme ka ọrụ dopant na-agbanwe agbanwe n'ofe wafer, na-eme ka arụ ọrụ mgbawa na ntụkwasị obi dịkwuo elu.

3. Na-eme ka Oxide Layer Consistency: Ezi ụkpụrụ okpomọkụ na-enyere aka iwepụ ọnụ-na-etiti thermal gradients n'oge oxidation, na-eme ka ọnụ ụzọ ámá oxide nha anya, dị oké mkpa maka àgwà transistor na-agbanwe agbanwe.

Mmechi

Ijikwa okpomọkụ dị mkpa na nrụpụta semiconductor. Site na njikwa okpomọkụ dị elu nke ọma, ndị na-emepụta nwere ike ibelata ntụpọ nke nrụgide okpomọkụ na-akpata, melite ịdị n'otu na usoro doping na oxidation, na n'ikpeazụ nweta mgbawa dị elu na ịrụ ọrụ ngwaọrụ ka mma.

Anyị nọ ebe a maka gị mgbe ị chọrọ anyị.

Biko dejupụta fọm ka ịkpọtụrụ anyị, anyị ga-enwekwa obi ụtọ inyere gị aka.