Kunyatso kudzora tembiricha kwakakosha mukugadzira semiconductor kudzivirira kushushikana kwekupisa, kunatsiridza kugadzikana kwemaitiro, uye kuwedzera chip performance. High-precision chillers inobatsira kudzikisa hurema senge makatsemuka uye delamination, kuve nechokwadi chedhoping yakafanana, uye kuchengetedza inopindirana oxide layer ukobvu-zvinhu zvakakosha mukusimudzira goho uye kuvimbika.

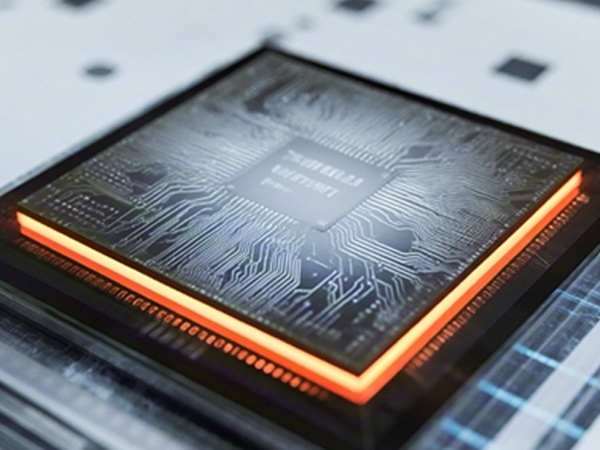

Sei Kudzora Kwekushisa Kwakakosha muSemiconductor Manufacturing?

Mukugadzira semiconductor, chaiyo tembiricha yekudzora inoita basa rakakosha mukuona chip mhando, kuita, uye goho rekugadzira. Kunyangwe kuderera kushoma kwetembiricha kunogona kukonzera shanduko huru mumabatiro enyama uye maitiro ekugadzirisa, izvo zvinogona kutungamirira kukukanganisika kana kutadza kwemudziyo.

Mhedzisiro yeThermal Stress

Semiconductor midziyo ine akawanda akaturikidzana emidziyo ane akasiyana coefficients ekuwedzera kwekupisa (CTE). Semuyenzaniso, silicon wafers, metal interconnects, uye dielectric layers dzinowedzera kana chibvumirano pamitengo yakasiyana panguva yekudziya nekukurumidza kana kutonhora. Kusawirirana uku kunogona kugadzira kushushikana kwekupisa, zvichitungamira kune dzakakomba nyaya dzekugadzira dzakadai se:

* Kutsemuka: Kutsemuka kwepamusoro kana mukati mewafers kunogona kukanganisa kutendeseka kwemuchina uye kukonzeresa kutadza kwechishandiso.

* Delamination: Mafirimu matete, akadai sesimbi kana dielectric layers, anogona kupatsanura, achinetesa mashandiro emagetsi echip uye kuvimbika kwenguva refu.

* Deformation yemaitiro: Zvimiro zvechishandiso zvinogona kuchinjika nekuda kwekushushikana, zvichikonzera matambudziko emagetsi senge kuvuza kana mapfupi maseketi.

Basa reHigh-Precision Temperature Control

Yepamberi tembiricha yekudzora masisitimu senge TEYU maindasitiri anopisa akagadzirirwa kuchengetedza kugadzikana kwetembiricha nekunyatso hunyanzvi. Semuyenzaniso, TEYU's ultrafast laser chiller inopa kurongeka kwekutonga kunosvika ± 0.08 ° C, kuve nechokwadi chekugadzikana kweiyo yakakosha semiconductor michina, inosanganisira etchers, deposition system, uye ion implanters.

Mabhenefiti e Precision Kutonhodza muSemiconductor Maitiro

1. Inodzivirira Thermal Stress Cracking: Nekuchengetedza yunifomu kutonhora, chillers inoderedza migumisiro yeCTE mismatch pakati pezvinhu zvakasiyana-siyana, zvinobudirira kuderedza dambudziko rekutsemuka uye delamination panguva yekupisa bhasikoro.

2. Inovandudza Doping Uniformity: Mukusimwa kweion uye kunotevera annealing, kugadzikana kwemamiriro ekupisa kunovimbisa kuwirirana kwekuita dopant mukati mewafer, kusimbisa chip performance uye kuvimbika.

3. Inovandudza Oxide Layer Consistency: Yakarurama tembiricha regulation inobatsira kubvisa kumucheto-ku-pakati-yepakati thermal gradients panguva oxidation, kuve nechokwadi yunifomu gedhi oxide ukobvu, kwakakosha kunoenderana transistor maitiro.

Mhedziso

Kudzora tembiricha kunokosha mukugadzira semiconductor. Iine yakakwirira-chaiyo yekupisa manejimendi, vagadziri vanogona kuderedza kuremara kunokonzerwa nekupisa kwekushushikana, kunatsiridza kufanana mune doping uye oxidation maitiro, uye pakupedzisira kuwana yakakwira chip goho uye zvirinani mashandiro echishandiso.

Tiripo nokuda kwenyu kana muchitida.

Ndapota zadza fomu kuti ubate nesu, uye isu tichafara kukubatsira.