Laser chillers suna da mahimmanci don tabbatar da ingancin wafer dicing a masana'antar semiconductor. Ta hanyar sarrafa zafin jiki da rage yawan damuwa na zafi, suna taimakawa rage burrs, chipping, da rashin daidaituwa na saman. Amintaccen sanyaya yana haɓaka kwanciyar hankali na laser kuma yana haɓaka rayuwar kayan aiki, yana ba da gudummawa ga mafi girman yawan guntu.

Menene Matsalolin Wafer Dicing na gama gari kuma ta yaya Chillers Laser Za Su Taimaka?

Wafers sune tushen kayan aiki a masana'antar semiconductor, suna aiki azaman ma'auni don haɗaɗɗun da'irori da sauran na'urorin microelectronic. Yawanci Anyi daga silicon monocrystalline, wafers suna da santsi, lebur, kuma yawanci 0.5 mm kauri, tare da diamita gama gari na 200 mm (inci 8) ko 300 mm (inci 12). Tsarin samarwa yana da rikitarwa sosai, wanda ya haɗa da tsarkakewar silicon, yankan ingot, polishing wafer, photolithography, etching, ion implantation, electroplating, gwajin wafer, kuma a ƙarshe, wafer dicing. Saboda kaddarorin kayansu, wafers suna buƙatar kulawa mai ƙarfi akan tsabta, laushi, da ƙimar lahani, saboda waɗannan suna tasiri kai tsaye aikin guntu.

Kalubalen Dicing Wafer gama gari

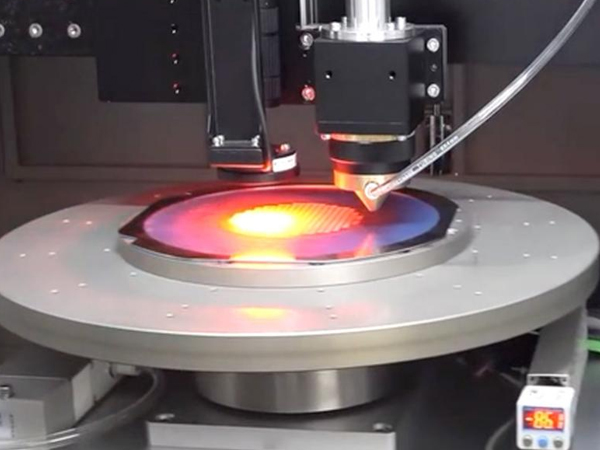

Fasahar dicing Laser ana karɓuwa sosai a cikin sarrafa wafer saboda babban daidaito da fa'idodin rashin haɗin gwiwa. Koyaya, wasu al'amura masu inganci na iya tasowa yayin dicing:

Burrs da Chipping: Waɗannan lahani galibi suna haifar da ƙarancin sanyaya ko sawa kayan aikin yanke. Haɓaka tsarin sanyaya ta haɓaka ƙarfin sanyi da haɓaka kwararar ruwa na iya taimakawa rage ɗumama mara daidaituwa da rage lalacewar gefen.

Rage Daidaiton Yanke: Ya haifar da rashin daidaiton inji, rashin kwanciyar hankali, ko sigogin yankan da ba daidai ba. Ana iya dawo da daidaito ta hanyar haɓaka ƙirar injina da haɓaka saitunan sigina.

Fuskokin Yanke Mara Madaidaici: Rigar ruwa, saitunan da basu dace ba, ko rashin daidaituwa na iya haifar da rashin daidaituwa. Kulawa na yau da kullun da gyaran injin suna da mahimmanci don tabbatar da yanke santsi.

Matsayin Laser Chillers a Wafer Dicing

Laser chillers suna taka muhimmiyar rawa wajen kiyaye aiki da kwanciyar hankali na Laser da tsarin gani da aka yi amfani da su wajen dicing. Ta hanyar isar da madaidaicin kulawar zafin jiki, suna hana raƙuman igiyar Laser da ke haifar da canjin zafin jiki, wanda ke da mahimmanci don kiyaye daidaiton yanke. Ingantacciyar sanyaya kuma yana rage danniya mai zafi yayin dicing, yana rage haɗarin ɓarna lattice, chipping, ko microcracks waɗanda zasu iya lalata ingancin wafer.

Bugu da kari, na'urorin sanyaya Laser suna amfani da tsarin sanyaya ruwa mai rufaffiyar madauki wanda ke ware da'irar sanyaya daga gurɓataccen waje. Tare da haɗaɗɗen saka idanu da tsarin ƙararrawa, suna haɓaka daɗaɗɗen amincin kayan aikin wafer dicing.

Kamar yadda ingancin wafer dicing yana tasiri kai tsaye ga amfanin guntu, haɗa ingantaccen abin sanyi na Laser yana taimakawa rage lahani na gama gari da ci gaba da ingantaccen aiki. Zaɓin sanyi mai dacewa dangane da nauyin zafin jiki na tsarin laser da yanayin aiki, tare da kiyayewa na yau da kullum, shine mabuɗin don tabbatar da kwanciyar hankali da ingantaccen aiki.

Muna nan a gare ku lokacin da kuke buƙatar mu.

Da fatan za a cika fom ɗin don tuntuɓar mu, kuma za mu yi farin cikin taimaka muku.