Ama-laser chiller abalulekile ekuqinisekiseni ikhwalithi ye-wafer dicing ekukhiqizeni ama-semiconductor. Ngokulawula izinga lokushisa kanye nokunciphisa ingcindezi yokushisa, basiza ukwehlisa ama-burrs, ukusika, nokungahambi kahle kwendawo. Ukupholisa okunokwethenjelwa kuthuthukisa ukuzinza kwe-laser futhi kwandise ukuphila kwemishini, kube nomthelela ekuvuneni okuphezulu kwama-chip.

Yiziphi Izinkinga Ezivamile Ze-Wafer Dicing futhi Ama-Laser Chiller Angasiza Kanjani?

Ama-wafers ayizinto eziyisisekelo ekwenziweni kwe-semiconductor, esebenza njengama-substrates amasekethe ahlanganisiwe namanye amadivaysi e-microelectronic. Ngokuvamile enziwa nge-silicon ye-monocrystalline, ama-wafer abushelelezi, ayisicaba, futhi ngokuvamile ugqinsi ngu-0.5 mm, anobubanzi obuvamile obungu-200 mm (amayintshi angu-8) noma angu-300 mm (amayintshi angu-12). Inqubo yokukhiqiza iyinkimbinkimbi kakhulu, ehlanganisa ukuhlanzwa kwe-silicon, ukusikwa kwe-ingot, ukupholisha i-wafer, i-photolithography, i-etching, ukufakwa kwe-ion, i-electroplating, ukuhlolwa kwe-wafer, futhi ekugcineni, ukudayela kwe-wafer. Ngenxa yezakhiwo zawo ezibonakalayo, ama-wafers afuna ukulawula okuqinile phezu kokuhlanzeka, ukucaba, namazinga okukhubazeka, njengoba lokhu kunomthelela ngokuqondile ekusebenzeni kwe-chip.

Izinselele Ezivamile Zokudayela Ngesiluga

Ubuchwepheshe bokudayela nge-laser bamukelwa kabanzi ekucutshungulweni kwe-wafer ngenxa yokunemba kwayo okuphezulu kanye nezinzuzo ezingathinteki. Nokho, kungase kuphakame izinkinga eziningana zekhwalithi ngesikhathi sokudayela:

I-Burrs and Chipping: Lezi zinkinga ngokuvamile zibangelwa ukupholisa okunganele noma amathuluzi okusika agugile. Ukuthuthukisa isistimu yokupholisa ngokuthuthukisa umthamo wokupholisa kanye nokwandisa ukugeleza kwamanzi kungasiza ekunciphiseni ukushisa okungalingani futhi kunciphise umonakalo onqenqemeni.

Ukunemba Okuncishisiwe Ukusika: Kubangelwa ukungami kahle komshini, amatafula okusebenza angazinzile, noma imingcele yokusika engalungile. Ukunemba kungabuyiswa ngokuthuthukisa ukulinganiswa komshini nokuthuthukisa izilungiselelo zepharamitha.

I-Uneven Cut Surfaces: Ukugqokwa kwe-blade, izilungiselelo ezingafanele, noma ukungahambi kahle kwe-spindle kungaholela ekuphambeni kahle kwendawo. Ukunakekelwa okuvamile nokulungiswa kabusha komshini kubalulekile ukuze kuqinisekiswe ukusika okushelelayo.

Iqhaza Lama-Laser Chillers ku-Wafer Dicing

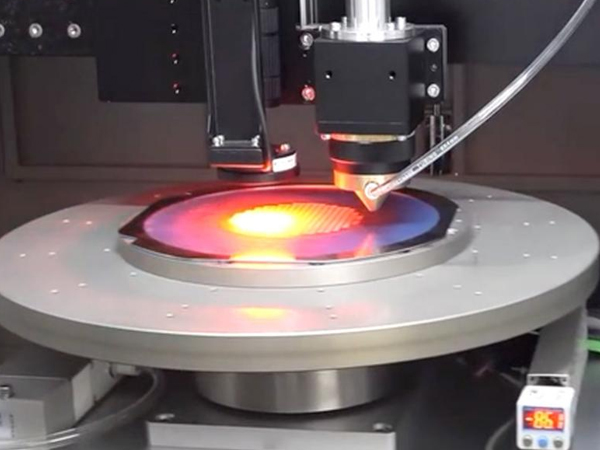

Ama-laser chiller adlala indima ebalulekile ekugcineni ukusebenza kanye nokuzinza kwe-laser kanye nesistimu yokubona esetshenziswa ekudayiseni kwe-wafer. Ngokuletha ukulawulwa kwezinga lokushisa okunembile, bavimbela ukukhukhuleka kwe-laser wavelength okubangelwa ukushintshashintsha kwezinga lokushisa, okubalulekile ekugcineni ukunemba kokusika. Ukupholisa okusebenzayo futhi kunciphisa ingcindezi yokushisa ngesikhathi sokudayela, kunciphisa ingcuphe yokuhlanekezelwa kwe-lattice, ukuchopha, noma ama-microcracks angonakalisa ikhwalithi ye-wafer.

Ukwengeza, ama-laser chiller asebenzisa isistimu yokupholisa amanzi evaliwe ehlukanisa isiyingi sokupholisa ekungcoleni kwangaphandle. Ngezinhlelo ezididiyelwe zokuqapha kanye ne-alamu, zithuthukisa kakhulu ukwethembeka kwesikhathi eside kwemishini yokudayela eyilucwecwe.

Njengoba ikhwalithi ye-wafer dicing ithinta ngokuqondile ukukhiqizwa kwe-chip, ukufaka i-laser chiller ethembekile kusiza ukunciphisa ukukhubazeka okuvamile nokugcina ukusebenza okungaguquki. Ukukhetha i-chiller efanelekile ngokusekelwe kumthwalo oshisayo wesistimu ye-laser nendawo yokusebenza, kanye nokugcinwa okuvamile, kuyisihluthulelo sokuqinisekisa ukusebenza okuzinzile nokusebenza kahle.

Sikhona ngenxa yakho uma usidinga.

Sicela ugcwalise ifomu ukuze uxhumane nathi, futhi sizokujabulela ukukusiza.