Izitshizi zeLaser zibalulekile ekuqinisekiseni umgangatho we-wafer dicing kwimveliso ye-semiconductor. Ngokulawula ubushushu kunye nokunciphisa uxinzelelo lwe-thermal, banceda ukunciphisa i-burrs, i-chips, kunye nezitenxo zomhlaba. Ukupholisa okuthembekileyo kwandisa uzinzo lwelaser kwaye kwandise ubomi besixhobo, kube negalelo kwisivuno esiphezulu se-chip.

Ziziphi iingxaki zeWafer Dicing eziqhelekileyo kwaye zinganceda njani iiLaser Chillers?

I-Wafers zizixhobo ezisisiseko kwimveliso ye-semiconductor, esebenza njengama-substrates kwiisekethe ezidibeneyo kunye nezinye izixhobo ze-microelectronic. Ngokuqhelekileyo zenziwe nge-silicon ye-monocrystalline, ii-wafers zigudile, zisicaba, kwaye zihlala zi-0.5 mm ubukhulu, kunye nobubanzi obuqhelekileyo be-200 mm (8 intshi) okanye i-300 mm (i-intshi eziyi-12). Inkqubo yemveliso intsonkothile kakhulu, ibandakanya ukucocwa kwesilicon, ukunqunyulwa kwe-ingot, ukupholiswa kwewafer, ifotolithography, i-etching, implantation ye-ion, i-electroplating, uvavanyo lwe-wafer, kwaye ekugqibeleni, i-wafer dicing. Ngenxa yeepropathi zazo zemathiriyeli, ii-wafers zifuna ulawulo olungqongqo phezu kobunyulu, ukuthamba, kunye nemilinganiselo yesiphene, njengoko ezi zichaphazela ngokuthe ngqo ukusebenza kwetshiphu.

Imingeni yeWafer Dicing eqhelekileyo

Itekhnoloji ye-laser dicing yamkelwa ngokubanzi ekusetyenzweni kwe-wafer ngenxa yokuchaneka kwayo okuphezulu kunye neenzuzo ezingadibanisiyo. Nangona kunjalo, imiba emininzi yomgangatho inokuvela ngexesha lokudayela:

IiBurrs kunye neChipping: Ezi ziphene zihlala zibangelwa kukupholisa okunganelanga okanye izixhobo zokusika ezigugileyo. Ukuphucula inkqubo yokupholisa ngokuphucula umthamo we-chiller kunye nokwandisa ukuhamba kwamanzi kunokuncedisa ukunciphisa ukufudumala okungalinganiyo kunye nokunciphisa umonakalo owenziweyo.

Ukunciphisa Ukuchaneka kokuNcitshiswa: Kubangelwa ukungasebenzi kakuhle komatshini, iitafile zokusebenza ezingazinzanga, okanye iiparitha zokusika ezingalunganga. Ukuchaneka kunokubuyiselwa ngokuphucula ukulinganisa umatshini kunye nokuphucula izicwangciso zeparameter.

I-Uneven Cut Surfaces: Ukunxitywa kwe-blade, iisetingi ezingafanelekanga, okanye ukungahambi kakuhle kwe-spindle kunokukhokelela kwizitenxo zomphezulu. Ukugcinwa rhoqo kunye nokulungiswa komatshini kubalulekile ukuqinisekisa ukusika okugudileyo.

Indima yeLaser Chillers kwiWafer Dicing

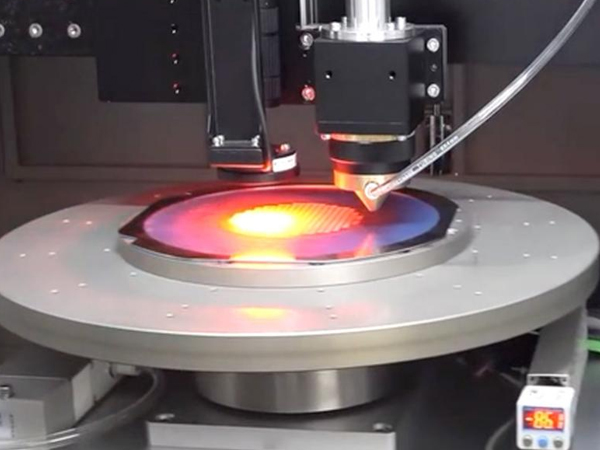

I-Laser chillers idlala indima ebalulekileyo ekugcineni ukusebenza kunye nokuzinza kwelaser kunye neenkqubo zokukhanya ezisetyenziswa kwi-wafer dicing. Ngokuzisa ulawulo oluchanekileyo lobushushu, banqanda i-laser wavelength drift okubangelwa kukuguquguquka kobushushu, okubalulekileyo ekugcineni ukuchaneka kokusika. Ukupholisa okusebenzayo kukwanciphisa uxinzelelo lobushushu ngexesha lokudayela, ukunciphisa umngcipheko wokugqwethwa kwe-lattice, ukuchopha, okanye ii-microcracks ezinokubeka esichengeni umgangatho we-wafer.

Ukongeza, ii-laser chillers zisebenzisa inkqubo yokupholisa amanzi evaliweyo ekwahlula isekethe yokupholisa kungcoliseko lwangaphandle. Ngeenkqubo ezidibeneyo zokubeka iliso kunye ne-alamu, ziphucula kakhulu ukuthembeka kwexesha elide kwezixhobo zokudayiza i-wafer.

Njengoko umgangatho we-wafer dicing uchaphazela ngokuthe ngqo isivuno se-chip, ukubandakanya i-laser chiller ethembekileyo kunceda ukunciphisa iziphene eziqhelekileyo kunye nokugcina ukusebenza okungaguqukiyo. Ukukhetha i-chiller efanelekileyo ngokusekelwe kumthwalo we-thermal we-laser kunye nokusingqongileyo okusebenzayo, kunye nokugcinwa rhoqo, ngundoqo ekuqinisekiseni ukusebenza okuzinzileyo nokusebenzayo.

Silapha ngenxa yakho xa usidinga.

Nceda ugcwalise ifomu ukuze uqhagamshelane nathi, kwaye siya kukuvuyela ukukunceda.