Laser chillers yog qhov tseem ceeb rau kev ua kom wafer dicing zoo hauv kev tsim khoom semiconductor. Los ntawm kev tswj qhov kub thiab txo qis thermal, lawv pab txo qis burrs, chipping, thiab nto irregularities. Kev cia siab txias ua kom muaj kev ruaj ntseg laser thiab txuas ntxiv cov cuab yeej siv lub neej, ua rau cov khoom siv hluav taws xob ntau dua.

Dab tsi yog qhov teeb meem Wafer Dicing thiab Laser Chillers pab tau li cas?

Wafers yog cov khoom siv tseem ceeb hauv kev tsim khoom semiconductor, ua cov substrates rau kev sib xyaw ua ke thiab lwm yam khoom siv microelectronic. Feem ntau ua los ntawm monocrystalline silicon, wafers yog du, tiaj tus, thiab feem ntau yog 0.5 hli tuab, nrog cov kab uas hla ntawm 200 hli (8 nti) lossis 300 hli (12 nti). Cov txheej txheem ntau lawm yog qhov nyuaj heev, suav nrog silicon purification, ingot slicing, wafer polishing, photolithography, etching, ion implantation, electroplating, wafer kuaj, thiab thaum kawg, wafer dicing. Vim lawv cov khoom siv, wafers xav tau kev tswj xyuas nruj ntawm purity, flatness, thiab cov nqi tsis xws luag, raws li cov kev cuam tshuam ncaj qha rau chip kev ua tau zoo.

Common Wafer Dicing Challenges

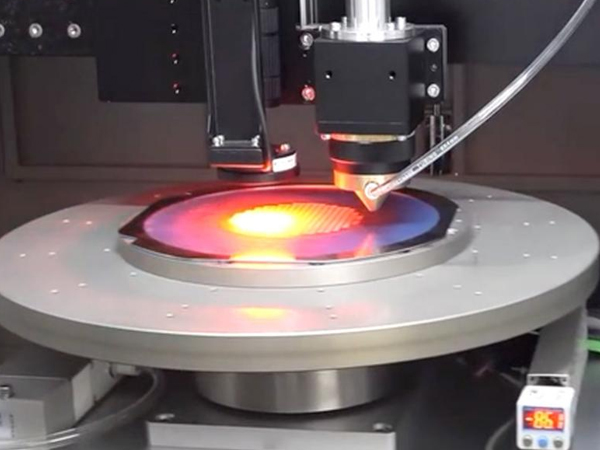

Laser dicing tshuab yog dav siv nyob rau hauv wafer ua vim nws siab precision thiab tsis-hu zoo. Txawm li cas los xij, ntau qhov teeb meem zoo yuav tshwm sim thaum lub sij hawm dicing:

Burrs thiab Chiping: Cov teeb meem no feem ntau tshwm sim los ntawm kev ua kom txias tsis txaus lossis hnav cov cuab yeej txiav. Txhim kho lub tshuab cua txias los ntawm kev txhim kho lub peev xwm chiller thiab nce dej ntws tuaj yeem pab txo qis cua sov tsis sib xws thiab txo qis ntug kev puas tsuaj.

Txo qhov raug txiav: Ua los ntawm lub tshuab tsis zoo, lub rooj ua haujlwm tsis ruaj khov, lossis tsis raug txiav tsis raug. Qhov tseeb tuaj yeem rov qab los ntawm kev txhim kho tshuab calibration thiab optimizing parameter nqis.

Tsis sib npaug Cut Surfaces: Hniav hnav, qhov chaw tsis raug, lossis spindle misalignment tuaj yeem ua rau muaj qhov tsis sib xws. Kev saib xyuas tsis tu ncua thiab tshuab recalibration yog qhov tseem ceeb los xyuas kom meej qhov kev txiav.

Lub luag haujlwm ntawm Laser Chillers hauv Wafer Dicing

Laser chillers ua lub luag haujlwm tseem ceeb hauv kev tswj kev ua haujlwm thiab kev ruaj ntseg ntawm laser thiab kho qhov muag tshuab siv hauv wafer dicing. Los ntawm kev xa cov kev tswj qhov kub thiab txias, lawv tiv thaiv laser wavelength drift los ntawm qhov kub thiab txias, uas yog qhov tseem ceeb rau kev tswj xyuas qhov tseeb. Kev ua kom txias zoo kuj txo qis thermal kev ntxhov siab thaum lub sij hawm dicing, txo qhov kev pheej hmoo ntawm kev cuam tshuam ntawm lattice, chipping, lossis microcracks uas tuaj yeem cuam tshuam wafer zoo.

Tsis tas li ntawd, laser chillers siv lub kaw-voj dej txias system uas cais cov cua txias los ntawm kev sib kis sab nraud. Nrog kev saib xyuas thiab lub tswb nrov, lawv txhim khu kev ntseeg tau ntev ntawm cov khoom siv wafer dicing.

Raws li wafer dicing zoo cuam tshuam ncaj qha rau nti tawm los, sib koom ua ke nrog lub laser chiller txhim khu kev qha pab txo qis qhov tsis xws luag thiab tswj kev ua haujlwm zoo ib yam. Xaiv lub chiller tsim nyog raws li lub laser system lub thermal load thiab kev khiav hauj lwm ib puag ncig, nrog rau kev saib xyuas tsis tu ncua, yog qhov tseem ceeb rau kev ua haujlwm ruaj khov thiab ua haujlwm tau zoo.

Peb nyob ntawm no rau koj thaum koj xav tau peb.

Thov ua kom tiav daim foos tiv tauj peb, thiab peb yuav zoo siab los pab koj.