Laser chillers akakosha pakuita kuti wafer dicing mhando mukugadzira semiconductor. Nekugadzirisa tembiricha uye kuderedza kushushikana kwekupisa, ivo vanobatsira kuderedza maburrs, chipping, uye kusarongeka kwepasi. Kutendeseka kutonhora kunowedzera kugadzikana kwelaser uye kunowedzera hupenyu hwemidziyo, zvichibatsira kune yakakwira chip goho.

Ndeapi Akajairwa Wafer Dicing Matambudziko uye Sei Laser Chillers Inobatsira?

Wafers ndiyo yekutanga zvinhu mukugadzira semiconductor, ichishanda sema substrates emasekete akabatanidzwa uye mamwe mamicroelectronic zvishandiso. Kazhinji inogadzirwa kubva kune monocrystalline silicon, mawafer anotsvedzerera, akati sandara, uye kazhinji 0.5 mm mukobvu, ane madhayamita akajairika e200 mm (8 inches) kana 300 mm (12 inches). Maitiro ekugadzira akaomarara zvakanyanya, anosanganisira silicon kucheneswa, ingot kucheka, wafer polishing, photolithography, etching, ion implantation, electroplating, wafer kuyedzwa, uye pakupedzisira, wafer dicing. Nekuda kwezvimiro zvavo zvenyama, wafer anoda kudzora kwakasimba pamusoro pekuchena, flatness, uye kuremara mitengo, sezvo izvi zvinokanganisa zvakananga chip performance.

Zvakajairwa Wafer Dicing Matambudziko

Laser dicing tekinoroji inotambirwa zvakanyanya mukugadziriswa kwewafer nekuda kweiyo yakanyanya kurongeka uye isina-kubata mabhenefiti. Nekudaro, akati wandei emhando dzemhando dzinogona kumuka panguva yekudhaira:

Burrs uye Chipping: Izvi zvinokanganisa zvinowanzokonzerwa nekusakwana kutonhora kana kupfeka maturusi ekucheka. Kuvandudza iyo yekutonhodza sisitimu nekusimudzira chiller simba uye kuwedzera kuyerera kwemvura kunogona kubatsira kuderedza kusaenzana kudziyisa uye kuderedza kukuvara kwemupendero.

Yakaderedzwa Yekucheka Kurongeka: Inokonzerwa nekushata kwemuchina chinzvimbo, isina kugadzikana matafura ekushanda, kana zvisizvo zvekucheka ma paramita. Kurongeka kunogona kudzoreredzwa nekuvandudza muchina calibration uye optimize parameter marongero.

Kusaenzana Kucheka Nzvimbo: Kupfeka kweblade, kuseta zvisina kufanira, kana kusarongeka kwe spindle kunogona kutungamira kune kusarongeka kwepamusoro. Kugara uchigadzirisa uye kugadzirisa muchina kwakakosha kuti uve nechokwadi chekucheka kwakatsetseka.

Basa reLaser Chillers muWafer Dicing

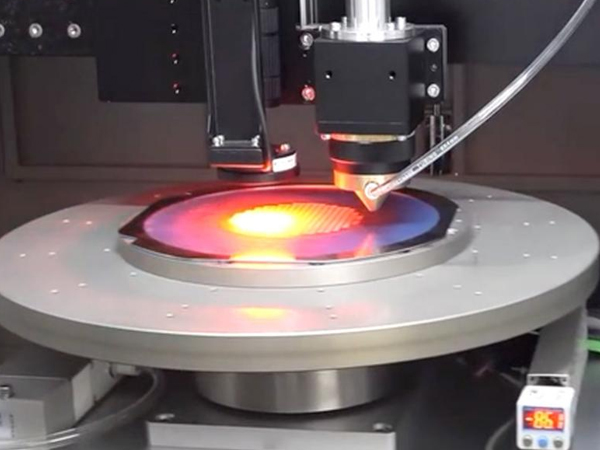

Laser chillers inoita basa rakakosha mukuchengetedza kuita uye kugadzikana kwelaser uye optical masisitimu anoshandiswa muwafer dicing. Nekuunza chaiyo tembiricha yekudzora, ivo vanodzivirira laser wavelength kudonha kunokonzerwa nekushanduka kwetembiricha, izvo zvakakosha pakuchengetedza kucheka chaiko. Kutonhora kunoshanda zvakare kunoderedza kushushikana kwemafuta panguva yekudhaira, kudzikisa njodzi yekukanganiswa kwelatisi, chipping, kana microcracks inogona kukanganisa wafer mhando.

Uye zvakare, laser chillers inoshandisa yakavharwa-loop mvura kutonhora sisitimu inoparadzanisa inotonhorera redunhu kubva kusvibiswa kwekunze. Nekubatanidzwa kwekutarisa uye alarm masisitimu, ivo vanosimudzira zvakanyanya kuvimbika kwenguva refu kwewafer dicing michina.

Sezvo wafer dicing mhando inokanganisa zvakananga chip goho, kubatanidza yakavimbika laser chiller kunobatsira kudzikisa hurema hwakajairika uye kuchengetedza kuita kunoenderana. Kusarudza chiller chakakodzera zvichibva pane iyo laser system yekupisa yekuremedza uye nharaunda yekushanda, pamwe chete nekugadzirisa nguva dzose, ndicho chinhu chakakosha pakuona kugadzikana uye kushanda kwakanaka.

Tiripo nokuda kwenyu kana muchitida.

Ndapota zadza fomu kuti ubate nesu, uye isu tichafara kukubatsira.