Ma laser chiller ndi ofunikira pakuwonetsetsa kuti makina opangira ma semiconductor ali abwino. Poyang'anira kutentha ndi kuchepetsa kupsinjika kwa kutentha, amathandizira kuchepetsa ma burrs, chipwirikiti, ndi kusakhazikika kwapamtunda. Kuziziritsa kodalirika kumathandizira kukhazikika kwa laser ndikukulitsa moyo wa zida, zomwe zimathandizira kuti pakhale zokolola zambiri.

Kodi Mavuto Odziwika Omwe A Wafer Dicing Ndi Chiyani Ndipo Ma Laser Chiller Angathandize Bwanji?

Ma Wafers ndizinthu zoyambira popanga semiconductor, zomwe zimagwira ntchito ngati mabwalo ophatikizika ndi zida zina zazing'ono zamagetsi. Nthawi zambiri amapangidwa kuchokera ku silicon ya monocrystalline, zopyapyala zimakhala zosalala, zosalala, ndipo nthawi zambiri zokhuthala ndi 0.5 mm, zokhala ndi mainchesi 200 mm (8 mainchesi) kapena 300 mm (12 mainchesi). Kapangidwe kake ndi kovuta kwambiri, komwe kumaphatikizapo kuyeretsa kwa silicon, kudula kwa ingot, kupukuta, kupukuta, kujambula, kujambula, kuyika ion, electroplating, kuyesa kwa wafer, ndipo pamapeto pake, dicing wafer. Chifukwa cha katundu wawo, zowotcha zimafuna kuwongolera mwamphamvu pa kuyera, kusalala, ndi kuchuluka kwa chilema, chifukwa izi zimakhudza mwachindunji magwiridwe antchito a chip.

Mavuto Omwe Amapezeka Pakutha Wafer

Ukadaulo wa laser dicing umatengedwa kwambiri pakukonza zopindika chifukwa cha kulondola kwake komanso zabwino zake zosalumikizana. Komabe, zovuta zingapo zitha kubuka panthawi ya dicing:

Burrs ndi Chipping: Zowonongeka izi nthawi zambiri zimabwera chifukwa cha kuzizira kosakwanira kapena zida zodula zomwe zatha. Kupititsa patsogolo makina ozizirira pokweza chiller ndikuwonjezera kuyenda kwamadzi kungathandize kuchepetsa kutentha kosafanana ndikuchepetsa kuwonongeka kwa m'mphepete.

Kuchedwetsa Kudulira Kochepa: Kumachitika chifukwa cha kusayika bwino kwa makina, ma tebulo osakhazikika, kapena magawo odulira olakwika. Kulondola kumatha kubwezeretsedwanso ndikuwongolera kusanja kwamakina ndi kukhathamiritsa makonzedwe a parameter.

Malo Odulidwa Osafanana: Kuvala kwamasamba, kusanja kosayenera, kapena kusanja kwa spindle kungayambitse kusokonekera. Kukonza nthawi zonse ndi kukonzanso makina ndikofunikira kuti zitsimikizike kuti kudula bwino.

Udindo wa Laser Chillers mu Wafer Dicing

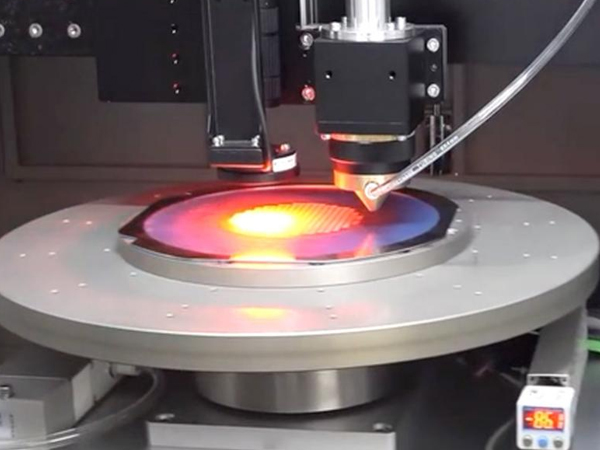

Ma laser chiller amatenga gawo lofunikira pakusunga magwiridwe antchito ndi kukhazikika kwa makina a laser ndi kuwala omwe amagwiritsidwa ntchito popanga dicing wafer. Popereka kuwongolera kolondola kwa kutentha, amateteza kutsetsereka kwa laser wavelength komwe kumachitika chifukwa cha kusinthasintha kwa kutentha, komwe ndikofunikira kuti mukhalebe olondola. Kuziziritsa kogwira mtima kumachepetsanso kupsinjika kwa kutentha panthawi ya dicing, kuchepetsa chiopsezo cha kupotoza kwa lattice, kupukuta, kapena ma microcracks omwe amatha kusokoneza mtundu wa wafer.

Kuphatikiza apo, zoziziritsa kukhosi za laser zimagwiritsa ntchito njira yoziziritsira madzi yotsekeka yomwe imalekanitsa kuzungulira koziziritsa ku kuipitsidwa kwakunja. Ndi machitidwe ophatikizika owunikira ndi ma alarm, amathandizira kwambiri kudalirika kwanthawi yayitali kwa zida zodulira zopindika.

Monga momwe ma dicing a wafer amakhudzira kukolola kwa tchipisi, kuphatikiza chotenthetsera chodalirika cha laser kumathandizira kuchepetsa zovuta zomwe wamba komanso kuchita mosasinthasintha. Kusankha chotenthetsera choyenera kutengera kuchuluka kwa matenthedwe amtundu wa laser ndi malo ogwirira ntchito, komanso kukonza nthawi zonse, ndikofunikira kuti pakhale ntchito yokhazikika komanso yabwino.

Tabwera chifukwa cha inu mukadzatifuna.

Chonde lembani fomu yolumikizana nafe, ndipo tidzakhala okondwa kukuthandizani.