DAVID LARCOMBE

A Bolton, Lancashire, Ingila factory na trailer manufacturer Indespension, takardar yankan kayan aiki ya ninka sau biyu a watan Disamba 2016 maye gurbin na'urar CO2 Laser-powered inji tare da Bystronic ByStar Fiber 6520 fiber Laser profiling cibiyar kudin kusan £ 800,000 (kimanin $1.3 miliyan; FIGURE 1). Laser fiber na 4kW yana da gado mai ƙarfin 6.5 × 2m, yana mai da shi injin fiber mafi girma da aka kawo zuwa yau a cikin kasuwar Burtaniya.

Daraktan sayen Indespension Steve Sadler yayi sharhi, "Mun yanke yafi 43A da pre-galv m karfe, da wasu aluminum, daga 1mm zuwa 12mm lokacin farin ciki. Har zuwa 3mm, da fiber Laser yanke sau uku da sauri fiye da CO2. Yana tashi ta hanyar 1mm karfe, samar da 10 ramuka / s. Amfanin wutsiyoyi, sau biyu da sauri ta hanyar kauri da yawa. A wani bugun jini, ya kawar da kwalaben da ke cikin masana'antarmu da injin CO2 ke haifar da rashin iya ci gaba da aikin yankan Laser da ke karuwa."

An sayi Laser fiber a cikin musayar juzu'i don daidaitaccen ƙarfin Bystronic CO2 samfurin zuwa Indespension da aka bayar a cikin 2009. Sadler ya tabbatar da cewa an sami farashin mai kyau don tsohuwar injin, duk da cewa ya yi aiki har zuwa sa'o'i 20 a rana, yana nuna darajar riƙewa azaman fa'ida ta siyan kayan aiki daga wannan masana'anta.

A farkon, babban dalilin zuba jari a Laser sabon shi ne don cimma wani girma mataki na a-gida iko a kan trailer samar da ajiye kudi na sa aikin fita zuwa sheet karfe subcontractors. Wani muhimmin abin la'akari shi ne daidaita tsarin ƙira da ƙira da kawo sabbin kayayyaki zuwa kasuwa cikin sauri.

Sadler ya ci gaba da cewa "Kafin 2009, yayin haɓaka samfura dole ne mu siya a cikin nau'i ɗaya, biyu, ko uku na sassan ƙarfe na samfur. "Masu kwangila ba su da sha'awar samar da irin wannan ƙananan adadi, don haka farashin ya kasance mai girma kuma ya dauki su makonni hudu zuwa shida don ba da samfurori. Idan muna buƙatar yin canje-canjen ƙira kuma mu koma ga mai kwangila don ƙarin samfurori-yana iya zama wani abu mai sauƙi kamar sabon saitin laka-wanda zai iya ƙara wani wata ko makamancin haka. yawanci watanni shida ko bakwai zuwa kasa da biyar, ko kuma na tirela da aka gyara daga wata uku ko hudu zuwa kasa da biyu."

Sadler ya yi nuni da cewa shekaru goma da suka gabata, ƴan tirelolin sun haɗa da sifofin yankan Laser, alhali a yau ana amfani da su sosai. Lalle ne, kayayyakin da aka tsara a kusa da babba capabilities na zamani Laser sabon inji. Ɗaya daga cikin fa'ida ita ce injin ɗin yana da daidai wanda abubuwan haɗin ke daidaitawa daidai da sauri yayin haɗuwa, ba tare da buƙatar daidaitawa mai ɗaukar lokaci ba.

Sauran fa'idar ita ce injina yana da sauri sosai, musamman tare da Laser fiber, cewa hanya ce mai inganci don ɗaukar nauyi daga abubuwan da aka haɗa ta hanyar haɗa ramuka da ramuka da yawa. Zai zama mai wahala sosai don haka rashin tattalin arziki don yin da hannu.

Laser yankan cell yana aiki dare da rana canje-canje da fitilu-fita a lokacin rani watanni, jimlar 18 zuwa 20 hours kowace rana, kwanaki biyar a mako. Domin sauran shekara, yana gudanar da motsi na rana kuma yana haskakawa na awanni 10 zuwa 12 a rana.

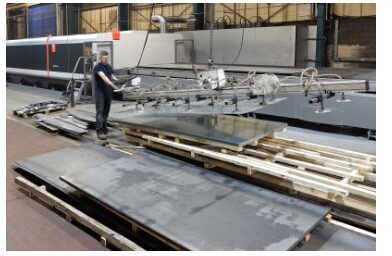

Indespension ya yanke shawarar kada a shigar da kayan aikin sarrafa kansa saboda yana aiwatar da girman takarda iri-iri, yana mai da matsala ta atomatik loading. Matsakaicin girman sassan ma yana da girma, kama daga sama da 5.8m zuwa ƙasa. Don haka halartar ma'aikata ya zama dole don gudanar da bambance-bambancen, don haka ana amfani da tsarin ɗagawa, tsarin ɗagawa na tsotsa don sarrafa takarda (FIGURE 2).

HOTO 2. Ana yin amfani da takarda a kunne da kashe tebur ɗin jirgin ByStar Fiber 6520 da hannu a Indespension ta amfani da na'urar ɗagawa.

Wannan yana gabatar da kamfani tare da matsala, duk da haka, idan aikin samarwa ya ƙunshi gida na wasu sassa masu sauƙi kawai kuma an yanke su daga takardar ma'auni na bakin ciki. Sake zagayowar yana da sauri sosai a cikin injin fiber Laser wanda mai aiki ba shi da lokacin gama girgiza sassa daga kwarangwal ɗin da ya gabata kafin a shirya takardar injin ɗin mai zuwa, ko don ɗaukar komai na gaba akan teburin jirgin.

Don haka, kamfanin yana tunanin haɗa ƙananan tags a cikin wasu shirye-shiryen yankan karfe ta yadda sassan da aka zayyana su kasance a manne da kwarangwal, suna ba da damar ɗaukar dukkan takardar da aka sarrafa zuwa tashar da ba ta layi ba, inda wani memba na ma'aikata zai iya taimakawa wajen cire abubuwan.

Daga cikin sassan karfen da aka yanke Laser da ke shiga cikin tirelolin Indespension, 80% na buƙatar nadawa. Saboda haka, lokacin da aka shigar da na'urar Laser na farko, an ba da birki na tandem daga mai kaya iri ɗaya (FIGURE 3).

Akwai fa'idodin haɓakawa daga samun injin yankan Laser da latsa birki daga mai kaya iri ɗaya a cikin cewa duk suna amfani da software iri ɗaya ta BySoft 7. Lokacin da aka tsara sabon sashi a cikin tsarin CAD na Indespension's SolidWorks CAD kuma ana fitar dashi zuwa software na sarrafa Bystronic, wanda kanta ya ƙunshi aikin 3D CAD / CAM mai ƙarfi, ƙirar ta haifar da shirin don yankan Laser da jerin don lankwasa ɓangaren, gami da matsayi na baya da shirin kayan aiki, don haka rage jinkiri da raguwa.

Software iri ɗaya, wanda ke da cikakkiyar damar kwaikwaiyo, yana da alhakin ƙaddamar da matsakaicin adadin sassa daga takarda, ƙirƙirar tsare-tsaren yanke da samar da bayyani na tsarin masana'anta, gami da samun dama ga samarwa da bayanan inji.

"Mun himmatu wajen jagorantar kasuwa ta fuskar kirkire-kirkire, inganci, da kuma ingancin muhalli," in ji Sadler. "Samun Laser fiber Laser na Bystronic yana taimaka mana don isar da waɗannan manufofin, da kuma samar da karuwar da ake buƙata a cikin ƙarfin samarwa. Har ila yau yana nuna ƙaddamar da ƙaddamar da masana'antun Burtaniya, wanda shine muhimmin ɓangare na ethos na kamfaninmu."