DAVID LARCOMBE

Kwi-Bolton, e-Lancashire, eNgilani i-factory yomvelisi we-trailer i-Indespension, i-sheet metal cutting imveliso iphindwe kabini emva kokutshintshwa kweDisemba 2016 yomatshini we-CO2 we-laser kunye ne-Bystronic ByStar Fiber 6520 i-fiber laser profiling center exabisa malunga ne-£ 800,000 (malunga ne-1.3 yezigidi zeedola; UMZO 1). I-4kW fiber laser ine-6.5 × 2m ibhedi yomthamo, iyenza ibe ngowona matshini mkhulu wefayibha othunyelwe ukuza kuthi ga ngoku kwimarike yase-UK.

Umlawuli wokuthenga we-Indespension uSteve Sadler uthe, "Sinqumle ubukhulu becala i-43A kunye ne-pre-galv yentsimbi ethambileyo, kunye ne-aluminium, ukusuka kwi-1mm ukuya kwi-12mm ubukhulu. Ukuya kuthi ga kwi-3mm, i-fiber laser inqumla kathathu ngokukhawuleza kune-CO2. Ibhabha ngentsimbi ye-1mm, ivelise imingxuma ye-10 / s. I-advantage iyancipha ngokuphindwe kabini, kodwa i-advantage iyancipha ngokuphindwe kabini i-gagess Sisebenza nge-stroke, kuphelise umqobo kumzi-mveliso wethu owabangelwa ngumatshini we-CO2 ongakwaziyo ukuqhubeka nomsebenzi wethu wokusika we-laser.

I-laser ye-fiber yathengwa kwi-part-exchange ye-equal-capacity-capacity ye-Bystronic CO2 imodeli kwi-Indespension ebonelelwe ngo-2009. I-Sadler iqinisekisile ukuba ixabiso elihle lifunyenwe kumatshini omdala, nangona lisebenze ukuya kwiiyure ze-20 ngosuku, ligxininisa ukugcinwa kwexabiso njengenzuzo yokuthenga izixhobo kulo mvelisi.

Ekuqaleni, esona sizathu sotyalo-mali ekusikeni kwe-laser yayikukufumana inqanaba elikhulu lolawulo lwangaphakathi lwendlu kwimveliso yetreyila kunye nokugcina iindleko zokubeka umsebenzi kwiikontraki zentsimbi. Olunye uqwalaselo olubalulekileyo yayikukulungelelanisa inkqubo yeprototyping kunye noyilo kunye nokuzisa iimveliso ezintsha ukuthengisa ngokukhawuleza.

“Ngaphambi kuka-2009, ngexesha lophuhliso lwemveliso kwafuneka sithenge iseti enye, ezimbini, okanye ezintathu zeprototype sheet metal parts,” waqhubeka uSadler. "Abancinci babengazimiselanga ukuvelisa amanani amancinci, ngoko ke ixabiso lalithande ukuba phezulu kwaye libathatha iiveki ezine ukuya kwezintandathu ukuhambisa iiprototypes. Ukuba sasidinga ukwenza utshintsho loyilo kwaye sibuyele kwi-subcontractor ye-prototypes eyongezelelweyo-inokuba yinto elula njengeseti entsha ye-mudguards-enokuthi yongeze enye inyanga kwi-indawo yokunciphisa ixesha, ngoku iyakwazi ukuvelisa i-indawo yokunciphisa ixesha. itreyila entsha ukusuka kwiinyanga ezintandathu okanye ezisixhenxe ukuya ngaphantsi kwesihlanu, okanye kwitreyila elungisiweyo ukusuka kwiinyanga ezintathu okanye ezine ukuya ngaphantsi kwesibini.

USadler wachaza ukuba kwishumi leminyaka eyadlulayo, iitreyila ezimbalwa ziye zabandakanya iimpawu zokusikwa kwelaser, ngelixa namhlanje zisetyenziswa kakhulu. Ewe, iimveliso ziyilwe malunga nesakhono esibonakalayo koomatshini banamhlanje bokusika i-laser. Enye ingenelo yeyokuba ukwenza oomatshini kuchanekile kangangokuba iinxalenye ezithile ziyadibana ngokuchanekileyo nangokukhawuleza ebudeni bendibano, ngaphandle kwemfuneko yokufaka ixesha elide.

Olunye uncedo kukuba ukwenza oomatshini kukhawuleza kakhulu, ngakumbi ngelaser yefiber, ukuba yindlela eneendleko eziphantsi yokuthatha ubunzima kumalungu ngokubandakanya imingxunya emininzi kunye neendawo zokubeka. Kuya kuba ngumsebenzi onzima kakhulu kwaye ngoko ke akukho qoqosho ukwenza ngesandla.

Iseli yokusika i-laser isebenza imini nobusuku kunye nezibane ezicinyiweyo kwiinyanga zasehlotyeni, zizonke iiyure ezili-18 ukuya kwezingama-20 ngosuku, iintsuku ezintlanu ngeveki. Kwintsalela yonyaka, iqhuba ishifti yosuku kwaye izibane zicinywe iiyure ezili-10 ukuya kwezili-12 ngosuku.

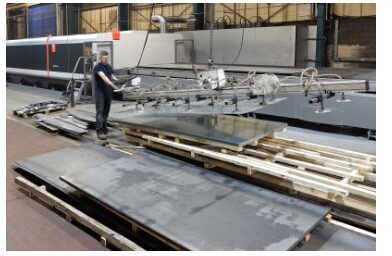

I-Indespension igqibe ekubeni ingafaki izixhobo ezizisebenzelayo kuba iqhuba iintlobo ngeentlobo zeesayizi zeshiti, isenza ukulayisha okuzenzekelayo kube yingxaki. Uluhlu lweesayizi zecandelo likhulu, ukusuka ngaphezulu kwe-5.8m ukuhla. Ukuhamba komsebenzi ke ngoko kuyimfuneko ukulawula ukuhlukahluka, ngoko ke i-manual, i-suction-pad lifting system isetyenziselwa ukuphatha amaphepha (UMZO 2).

UMZOBE 2. Ukuphathwa kweshiti ngaphakathi nangaphandle kwetafile ye-ByStar Fiber 6520 ye-shuttle table yenziwa ngesandla kwi-Indespension kusetyenziswa isixhobo sokuphakamisa iphedi yokufunxa.

Oku kunika inkampani ingxaki, nangona kunjalo, ukuba ukuveliswa kwemveliso kubandakanya indlwane yeendawo ezimbalwa ezilula kwaye zisikwe kwiphepha elincinane. Umjikelo wokusika ukhawuleza kakhulu kumatshini we-fiber laser kangangokuba umqhubi akanalo ixesha lokugqiba ukushukuma iinxalenye kwi-skeleton yangaphambili ngaphambi kokuba ishidi lomatshini elilandelayo lilungile, okanye ukulayisha okungenanto okulandelayo kwitafile ye-shuttle.

Ke, inkampani icinga ngokubandakanya i-micro-tags kwiinkqubo zokusika isinyithi ukuze iindawo ezifakwe kwiprofayili zihlale zincanyathiselwe kwi-skeleton, evumela ukuba lonke iphepha elicwangcisiweyo lidluliselwe kwisikhululo esingekho kwi-intanethi, apho elinye ilungu labasebenzi linokunceda ukususa amacandelo.

Kwiinxalenye zentsimbi ezisikiweyo ze-laser ezingena kwiitreyila ze-Indespension, i-80% ifuna ukusongwa. Ngokufanelekileyo, xa umatshini wokuqala we-laser ufakwe, i-tandem press brake evela kumthengisi ofanayo yanikezelwa ngokunjalo (UMZO 3).

Kukho iinzuzo zemveliso ekufumaneni umatshini wokusika i-laser kwaye ucinezele iziqhoboshi kumthengisi ofanayo kuba bonke basebenzisa i-software ye-BySoft 7 efanayo. Xa icandelo elitsha liyilwe kwinkqubo ye-Indespension ye-SolidWorks CAD kwaye ithunyelwe kwi-software yokulawula i-Bystronic, yona ngokwayo iqulethe ukusebenza kwe-3D CAD / CAM enamandla, imodeli ivelisa inkqubo yokusika i-laser kunye nolandelelwano lokugoba icandelo, kubandakanywa isikhundla se-backgauge kunye nesicwangciso sesixhobo, ngaloo ndlela ukunciphisa ukulibaziseka kunye nokunciphisa ixesha.

Isoftware efanayo, enekhono elipheleleyo lokulinganisa, inoxanduva lokuzalela inani eliphezulu leenxalenye ukusuka kwiphepha, ukudala izicwangciso zokusika kunye nokubonelela ngenkcazo yenkqubo yokuvelisa, kubandakanywa ukufikelela ngokukhawuleza kwimveliso kunye nedatha yomatshini.

“Sizibophelele ekukhokeleni imarike ngokwemigaqo yokusungula izinto ezintsha, umgangatho, kunye neziqinisekiso zokusingqongileyo,” uqukumbele ngelitshoyo uSadler. "Ukufumana i-Bystronic fiber laser kusinceda ukuba sifezekise ezi njongo, kunye nokubonelela ngokunyuka okufunekayo kumandla okuvelisa. Kwakhona kubonisa ukuzinikela kwethu kwimveliso yase-UK, eyona nxalenye ebalulekileyo ye-ethos yenkampani yethu."