Yanke Laser na iya fuskantar batutuwa kamar bursu, yankewar da ba ta cika ba, ko manyan wuraren da zafi ya shafa saboda saitunan da ba su dace ba ko rashin kula da zafi. Gano tushen tushen da yin amfani da hanyoyin da aka yi niyya, kamar inganta wutar lantarki, kwararar iskar gas, da yin amfani da injin sanyaya Laser, na iya inganta haɓakar ingancin yanke, daidaito, da tsawon kayan aiki.

Matsalolin gama gari a cikin Yanke Laser da Yadda ake Hana su

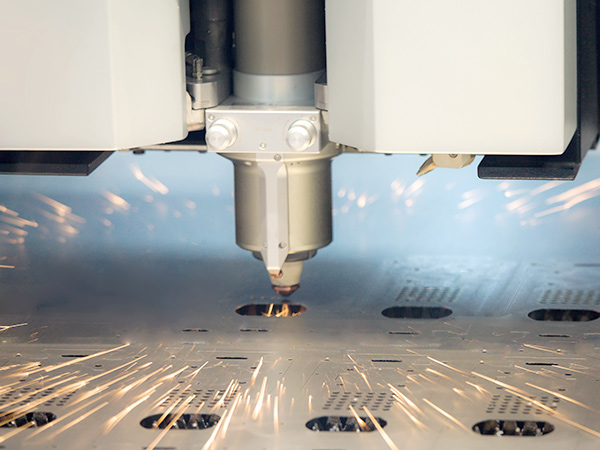

Yanke Laser dabara ce da ake amfani da ita sosai a masana'antar zamani, wacce aka sani da daidaito da inganci. Koyaya, idan ba a sarrafa shi da kyau ba, lahani da yawa na iya tasowa yayin aiwatarwa, yana shafar ingancin samfur da ingancin samarwa. Da ke ƙasa akwai lahani na yankan Laser na yau da kullun, abubuwan da suke haifar da su, da mafita masu inganci.

1. M Gefuna ko Burrs a kan Yanke saman

Dalilai: 1) Ƙarfin da ba daidai ba ko saurin yankewa, 2) Nisa mara kyau, 3) ƙarancin iskar gas, 4) gurɓataccen kayan gani ko abubuwan da aka haɗa.

Magani: 1) Daidaita ƙarfin Laser da sauri don dacewa da kauri na kayan, 2) Daidaita nesa mai nisa daidai, 3) Tsaftace da kula da kan laser akai-akai, 4) Inganta matsin gas da sigogi masu gudana.

2. Zubewa ko Kumburi

Dalilai: 1) Rashin isassun iskar gas, 2) Ƙarfin Laser mai yawa, 3) datti ko oxidized kayan saman.

Magani: 1) Ƙara yawan taimakon iskar gas, 2) Ƙarƙashin wutar lantarki kamar yadda ake bukata, 3) Tabbatar cewa saman abu yana da tsabta kafin yanke.

3. Babban yankin da zafi ya shafa (HAZ)

Dalilai: 1) Ƙarfi mai yawa, 2) Gudun yankan hankali, 3) Rashin isasshen zafi.

Magani: 1) Rage ƙarfi ko ƙara saurin gudu, 2) Yi amfani da injin sanyaya Laser don sarrafa zafin jiki da haɓaka sarrafa zafi.

4. Yankewar da bai cika ba

Dalilai: 1) Rashin isassun wutar lantarki, 2) Ƙimar katako, 3) Ƙunƙara ko lalacewa.

Magani: 1) Bincika kuma maye gurbin tushen laser idan tsufa, 2) Daidaita hanyar gani, 3) Sauya ruwan tabarau ko nozzles idan an sawa.

5. Burrs akan Bakin Karfe ko Aluminum

Dalilai: 1) Babban abin nuna kyama na kayan, 2) ƙarancin tsabta na taimakon gas

Magani: 1) Yi amfani da iskar iskar nitrogen mai tsafta (≥99.99%), 2) Daidaita matsayin mayar da hankali don yanke tsafta

Matsayin Masana'antu Laser Chillers a cikin Inganta Yanke Ingancin

Laser chillers suna taka muhimmiyar rawa wajen rage lahani da kuma tabbatar da daidaitaccen aikin yankan ta hanyar ba da fa'idodi masu zuwa:

Ta hanyar ganowa da magance waɗannan lahani na kowa, masana'antun na iya samun sakamako mafi kyau a cikin ayyukan yankan Laser. Aiwatar da abin dogara kwantar da hankali mafita, kamar masana'antu Laser chillers , kara habaka samfurin ingancin, tsari kwanciyar hankali, da kuma kayan aiki tsawon rai.

Muna nan a gare ku lokacin da kuke buƙatar mu.

Da fatan za a cika fom ɗin don tuntuɓar mu, kuma za mu yi farin cikin taimaka muku.