Ho itšeha ka laser ho ka kopana le mathata a kang li-burrs, ho seha ho sa fellang, kapa libaka tse kholo tse anngoeng ke mocheso ka lebaka la maemo a sa nepahalang kapa taolo e fosahetseng ea mocheso. Ho tseba lisosa tsa metso le ho sebelisa litharollo tse lebisitsoeng, joalo ka ho ntlafatsa matla, phallo ea khase, le ho sebelisa laser chiller, ho ka ntlafatsa haholo boleng ba ho itšeha, ho nepahala le nako ea bophelo ea lisebelisoa.

Mefokolo e Tloaelehileng ea ho Seha Laser le Mokhoa oa ho Ba Thibela

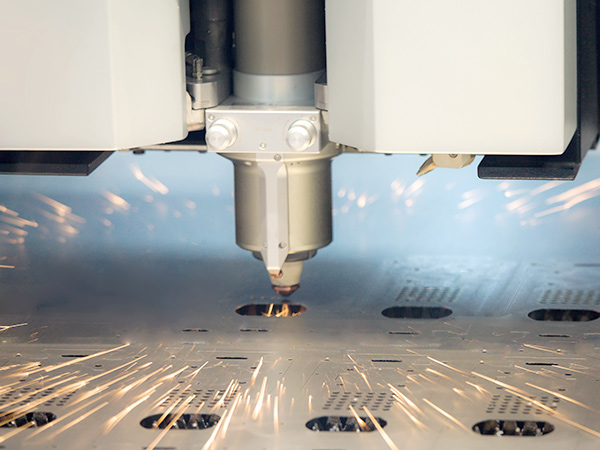

Ho itšeha ka laser ke mokhoa o sebelisoang haholo tlhahisong ea sejoale-joale, e tsebahalang ka ho nepahala le ho sebetsa hantle. Leha ho le joalo, haeba e sa laoloe hantle, liphoso tse 'maloa li ka hlaha nakong ea ts'ebetso, tse amang boleng ba sehlahisoa le katleho ea tlhahiso. Ka tlase ke atileng ka ho fetisisa laser ho itšeha mefokolo, lisosa tsa bona, le tharollo e sebetsang.

1. Rough Edges kapa Burrs ka Cut Surface

Lisosa: 1) Matla a sa nepahalang kapa lebelo la ho itšeha, 2) Sebaka se sa nepahalang sa sebaka, 3) Khatello e tlase ea khase, 4) Optics e silafetseng kapa likaroloana

Litharollo: 1) Fetola matla le lebelo la laser ho tsamaisana le botenya ba thepa, 2) Beakanya sebaka se tsepamisitsoeng hantle, 3) Hloekisa le ho boloka hlooho ea laser khafetsa, 4) Ntlafatsa khatello ea khase le liparamente tsa phallo.

2. Mokeli-keli kapa Porosity

Lisosa: 1) Phallo ea khase e sa lekaneng, 2) Matla a laser a feteletseng, 3) Sebaka se litšila kapa se nang le oxidized

Litharollo: 1) Eketsa sekhahla sa phallo ea khase, 2) Matla a tlase a laser ha ho hlokahala, 3) Netefatsa hore libaka tsa thepa li hloekile pele u seha.

3. Sebaka se Seholo se Ametsoeng ke Mocheso (HAZ)

Lisosa: 1) Matla a feteletseng, 2) Lebelo le liehang ho itšeha, 3) Ho se be le mocheso o lekaneng

Litharollo: 1) Fokotsa matla kapa eketsa lebelo, 2) Sebelisa laser chiller ho laola mocheso le ho ntlafatsa taolo ea mocheso.

4. Ho Seha ho sa Feleng

Lisosa: 1) Matla a laser a sa lekaneng, 2) ho sesa hantle ha Beam, 3) Nozzle e tsofetseng kapa e senyehileng.

Litharollo: 1) Sheba le ho khutlisa mohloli oa laser ha o tsofala, 2) Lokisa tsela ea optical, 3) Kenya lilense tse tsepamisitsoeng kapa li-nozzles ha li aparoa.

5. Burrs ka Stainless Steel kapa Aluminium

Lisosa: 1) High reflectivity ea lintho tse bonahalang, 2) Low bohloeki ba ho thusa khase

Litharollo: 1) Sebelisa khase ea naetrojene e hloekileng haholo (≥99.99%), 2) Fetola maemo bakeng sa likheo tse hloekileng.

Karolo ea Li-Laser Chillers tsa Indasteri ho Ntlafatsa Boleng ba ho Seha

Li-chiller tsa laser li bapala karolo ea bohlokoa ho fokotsa liphoso le ho netefatsa ts'ebetso e tsitsitseng ea ho itšeha ka ho fana ka melemo e latelang:

Ka ho hlwaya le ho sebetsana le liphoso tsena tse tloaelehileng, bahlahisi ba ka fihlela litholoana tse ntle ts'ebetsong ea ho itšeha ka laser. Ho kenya ts'ebetsong litharollo tse tšepahalang tsa ho pholisa, joalo ka li-laser chiller tsa indasteri , ho eketsa boleng ba sehlahisoa, botsitso ba ts'ebetso le bophelo bo bolelele ba lisebelisoa.

Re mona bakeng sa hau ha o re hloka.

Ka kopo tlatsa foromo ho ikopanya le rona, 'me re tla thabela ho u thusa.