Ukusika nge-laser kungase kuhlangabezane nezinkinga ezifana nama-burrs, ukusikeka okungaphelele, noma izindawo ezinkulu ezithinteke ukushisa ngenxa yezilungiselelo ezingafanele noma ukuphathwa kabi kokushisa. Ukuhlonza izimbangela zezimpande nokusebenzisa izixazululo eziqondiwe, ezifana nokwandisa amandla, ukugeleza kwegesi, nokusebenzisa i-laser chiller, kungathuthukisa kakhulu ikhwalithi yokusika, ukunemba, nempilo yemishini.

Ukukhubazeka Okujwayelekile Ekunqumeni I-Laser kanye Nendlela Yokuvimbela

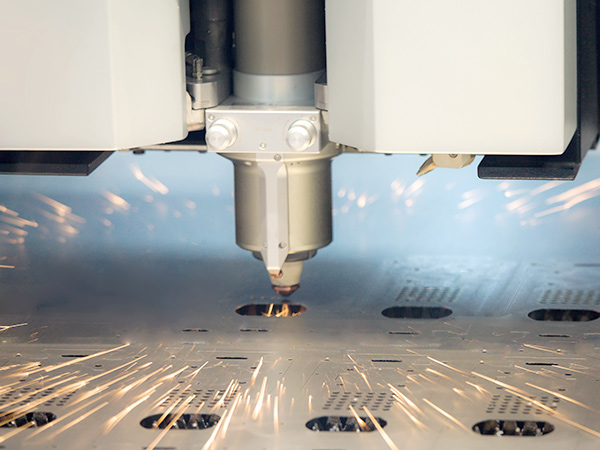

Ukusika i-laser kuyindlela esetshenziswa kakhulu ekukhiqizeni kwanamuhla, eyaziwa ngokunemba nokusebenza kahle kwayo. Kodwa-ke, uma kungalawulwa kahle, kungase kuvele amaphutha amaningana phakathi nenqubo, kuthinte ikhwalithi yomkhiqizo nokusebenza kahle kokukhiqiza. Ngezansi kukhona amaphutha ajwayelekile okusika i-laser, izimbangela zawo, nezixazululo ezisebenzayo.

1. Ama-rough Edges noma amaBurrs ku-Cut Surface

Izimbangela: 1) Amandla angalungile noma isivinini sokusika, 2) Ibanga lokugxila elingalungile, 3) Ingcindezi yegesi ephansi, 4) I-Optics engcolile noma izingxenye

Izixazululo: 1) Lungisa amandla e-laser kanye nesivinini ukuze uhambisane nogqinsi lwezinto, 2) Linganisa ibanga lokugxila ngokunembile, 3) Hlanza futhi ugcine ikhanda le-laser njalo, 4) Lungiselela ingcindezi yegesi kanye nemingcele yokugeleza

2. Imfucumfucu noma i-Porosity

Izimbangela: 1) Ukugeleza kwegesi okunganele, 2) Amandla e-laser amaningi, 3) Indawo engcolile noma ene-oxidized

Izixazululo: 1) Khulisa izinga lokugeleza kwegesi elisizayo, 2) Amandla e-laser aphansi njengoba kudingeka, 3) Qinisekisa ukuthi izindawo ezibonakalayo zihlanzekile ngaphambi kokusika.

3. Indawo Enkulu Ethinteke Ukushisa (HAZ)

Izimbangela: 1) Amandla amaningi, 2) Ijubane lokusika kancane, 3) Ukungashisi kahle

Izixazululo: 1) Yehlisa amandla noma ukhuphule isivinini, 2) Sebenzisa i-laser chiller ukulawula izinga lokushisa futhi uthuthukise ukuphathwa kokushisa.

4. Ukusika Okungaphelele

Izimbangela: 1) Amandla e-laser anganele, 2) Ukungahambi kahle kwe-beam, 3) I-nozzle egugile noma eyonakele

Izixazululo: 1) Hlola bese ubuyisela umthombo we-laser uma uguga, 2) Hlela kabusha indlela yokubona, 3) Faka esikhundleni amalensi okugxilwa kuwo noma imibhobho uma egqokile.

5. AmaBurrs on Stainless Steel noma Aluminium

Izimbangela: 1) Ukubonakala okuphezulu kwezinto ezibonakalayo, 2) Ukuhlanzeka okuphansi kwegesi yokusiza

Izixazululo: 1) Sebenzisa igesi ye-nitrogen ehlanzeke kakhulu (≥99.99%), 2) Lungisa indawo yokugxila yokusikeka okuhlanzekile

Iqhaza Lama-Industrial Laser Chillers Ekuthuthukiseni Ikhwalithi Yokusika

Ama-laser chiller adlala indima ebalulekile ekwehliseni amaphutha futhi aqinisekise ukusebenza okungaguquki kokusika ngokunikeza izinzuzo ezilandelayo:

Ngokuhlonza nokubhekana nalezi ziphambeko ezivamile, abakhiqizi bangathola imiphumela engcono emisebenzini yokusika i-laser. Ukusebenzisa izixazululo zokupholisa ezinokwethenjelwa, ezifana nama -laser chiller ezimbonini , kuthuthukisa futhi ikhwalithi yomkhiqizo, ukuqina kwenqubo, nokuphila isikhathi eside kwemishini.

Sikhona ngenxa yakho uma usidinga.

Sicela ugcwalise ifomu ukuze uxhumane nathi, futhi sizokujabulela ukukusiza.