Goynta laser-ka waxa laga yaabaa inay la kulanto arrimo ay ka mid yihiin Burrs, goyn aan dhammaystirnayn, ama aagagga kulaylku saameeyay oo waaweyn oo ay ugu wacan tahay goobo aan habboonayn ama maaraynta kulaylka oo liita. Aqoonsiga sababaha xididka iyo adeegsiga xalalka la beegsanayo, sida wanaajinta awoodda, socodka gaaska, iyo isticmaalka qaboojiyaha laysarka, waxay si weyn u wanaajin kartaa tayada goynta, saxnaanta, iyo cimriga qalabka.

Cilladaha Caadiga ah ee Goynta Laser-ka iyo Sida Looga Hortago

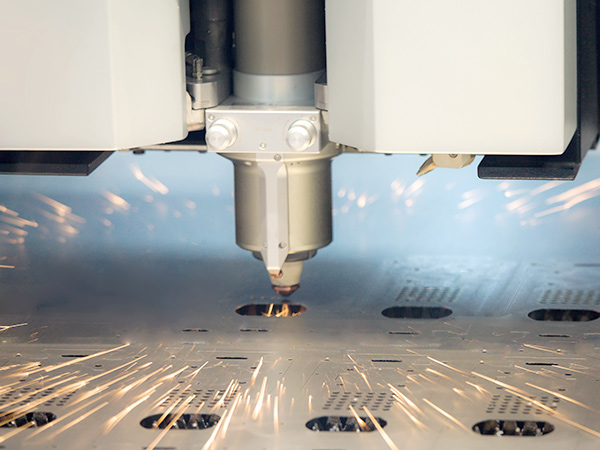

Goynta laser waa farsamo si weyn loo isticmaalo wax soo saarka casriga ah, oo loo yaqaan saxnaanta iyo waxtarkeeda. Si kastaba ha noqotee, haddii aan si habboon loo koontaroolin, cillado dhowr ah ayaa laga yaabaa inay soo baxaan inta lagu jiro habka, oo saameeya tayada alaabta iyo waxtarka wax soo saarka. Hoos waxaa ku yaal cilladaha goynta laser-ka ee ugu caansan, sababaha, iyo xalalka waxtarka leh.

1. Cidhifyo qallafsan ama Burrs oo ku yaal dusha sare ee la jaray

Sababaha: 1) Awood aan habboonayn ama xawaar gooyn, 2) Focal Focal oo khaldan, 3) Cadaadis gaas oo hooseeya, 4) Qalabka indhaha ama qaybaha wasakhaysan

Xalka: 1) Hagaaji awooda laysarka iyo xawaaraha si aad ugu dhigmato dhumucda walxaha

2. Dhibic ama xumaan

Sababaha: 1) Qulqulka gaaska oo aan ku filnayn, 2) Awoodda laysarka oo xad dhaaf ah, 3) Walax wasakh ah ama oksaydhaysan

Xalka: 1) Kordhi heerka qulqulka gaaska caawinta, 2) awoodda leysarka hoose marka loo baahdo, 3) Hubi in sagxadaha alaabtu ay nadiif yihiin ka hor inta aan la jarin

3. Aagga Weyn ee kulaylku saameeyay (HAZ)

Sababaha: 1) Awood xad dhaaf ah, 2) Xawaaraha jarista oo gaabis ah, 3) Kulayl aan ku filnayn

Xalka: 1) Yaree awoodda ama kordhi xawaaraha, 2) Isticmaal qaboojiyaha laysarka si aad u xakamayso heerkulka una hagaajiso maaraynta kulaylka

4. Gooyn aan dhamaystirnayn

Sababaha: 1) Awood la'aanta laysarka oo aan ku filnayn, 2) Laydhka si khaldan u-habboon, 3) Duub xidhan ama dhaawacmay

Xalka: 1) Hubi oo beddel isha laysarka haddii da'da, 2) Dib u hagaajiso dariiqa indhaha, 3) Beddel muraayadaha indhaha ama sanbabada haddii la xidho

5. Burrs on Steel ahama aluminium

Sababaha: 1) Milicsiga sare ee maaddada, 2) Nadiifin hooseeya ee gaasta caawinta

Xalka: 1) Isticmaal gaaska nitrogen-nadiifinta sare leh (≥99.99%), 2) Hagaaji booska diiradda si loo gooyo nadiifinta

Doorka qaboojiyeyaasha laser-ka warshadaha ee hagaajinta tayada goynta

Qaboojiyaha Laser-ku waxay door muhiim ah ka ciyaaraan yaraynta cilladaha iyo hubinta waxqabadka goynta joogtada ah iyagoo bixinaya faa'iidooyinka soo socda:

Aqoonsiga iyo wax ka qabashada cilladahan caadiga ah, soosaarayaashu waxay ku gaari karaan natiijooyin wanaagsan hawlgallada goynta laysarka. Hirgelinta xalalka qaboojinta lagu kalsoonaan karo, sida qaboojiyeyaasha laysarka warshadaha , waxay sii kordhiyaan tayada alaabta, xasiloonida habka, iyo qalabka cimriga dheer.

Waanu kuu joognaa marka aad noo baahan tahay.

Fadlan buuxi foomka si aad nala soo xiriirto, waana ku faraxsanahay inaan ku caawinno.