Kudula kwa laser kumatha kukumana ndi zovuta monga ma burrs, mabala osakwanira, kapena madera akuluakulu omwe amakhudzidwa ndi kutentha chifukwa cha kusanjikiza kolakwika kapena kusawongolera bwino kwa kutentha. Kuzindikira zomwe zimayambitsa ndikugwiritsa ntchito njira zomwe zikuwatsogolera, monga kukhathamiritsa mphamvu, kuyenda kwa gasi, ndi kugwiritsa ntchito chopondera cha laser, kumatha kupititsa patsogolo kwambiri kudula, kulondola, ndi moyo wa zida.

Zowonongeka Wamba mu Kudula kwa Laser ndi Momwe Mungapewere

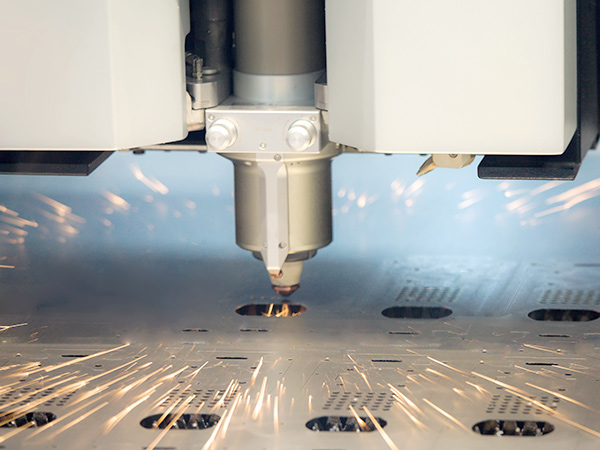

Kudula kwa laser ndi njira yomwe imagwiritsidwa ntchito kwambiri popanga zamakono, zomwe zimadziwika kuti ndizolondola komanso zogwira mtima. Komabe, ngati sizikuyendetsedwa bwino, zolakwika zingapo zitha kuchitika panthawiyi, zomwe zimakhudza mtundu wazinthu komanso magwiridwe antchito. M'munsimu muli ambiri laser kudula zilema, zomwe zimayambitsa, ndi njira zothetsera.

1. Zovuta M'mphepete kapena Burrs pa Cut Surface

Zomwe zimayambitsa: 1) Mphamvu yolakwika kapena liwiro lodulira, 2) Kutalikirana kolakwika, 3) Kuthamanga kwa mpweya wochepa, 4) Optics kapena zinthu zina zoipitsidwa.

Zothetsera: 1) Sinthani mphamvu ya laser ndi liwiro kuti zigwirizane ndi makulidwe azinthu, 2) Sinthani mtunda wokhazikika molondola, 3) Yeretsani ndikusunga mutu wa laser nthawi zonse, 4) Konzani kuthamanga kwa mpweya ndi magawo oyenda

2. Dola kapena Porosity

Zomwe zimayambitsa: 1) Kusakwanira kwa gasi, 2) Kuchuluka kwa laser mphamvu, 3) Zonyansa kapena oxidized zinthu pamwamba

Zothetsera: 1) Wonjezerani kuchuluka kwa gasi wothandizira, 2) Kuchepetsa mphamvu ya laser ngati pakufunika, 3) Onetsetsani kuti zinthu zakuthupi ndizoyera musanadulire.

3. Malo Okhudzidwa ndi Kutentha Kwakukulu (HAZ)

Zomwe zimayambitsa: 1) Mphamvu zambiri, 2) Kuthamanga kwapang'onopang'ono, 3) Kutaya kutentha kosakwanira

Zothetsera: 1) Chepetsani mphamvu kapena onjezerani liwiro, 2) Gwiritsani ntchito chozizira cha laser kuti muchepetse kutentha ndikuwongolera kutentha.

4. Mabala Osakwanira

Zomwe zimayambitsa: 1) Kusakwanira kwa mphamvu ya laser, 2) Kuyika molakwika kwa mtengo, 3) Kuwonongeka kapena kuwonongeka kwa nozzle

Zothetsera: 1) Yang'anani ndikusintha magwero a laser ngati akukalamba, 2) Sinthani njira yowunikira, 3) Bwezerani magalasi owunikira kapena ma nozzles ngati avala

5. Burrs pa Stainless Steel kapena Aluminium

Zomwe zimayambitsa: 1) Kuwonekera kwakukulu kwa zinthuzo, 2) Kuyeretsa kochepa kwa mpweya wothandizira

Zothetsera: 1) Gwiritsani ntchito mpweya wa nayitrogeni woyengedwa kwambiri (≥99.99%), 2) Sinthani malo olunjika a mabala oyeretsa

Udindo wa Industrial Laser Chillers Pakukweza Ubwino Wodula

Ma laser chiller amatenga gawo lofunikira kwambiri pakuchepetsa zolakwika ndikuwonetsetsa kuti magwiridwe antchito osasinthasintha popereka maubwino awa:

Pozindikira ndi kuthana ndi zolakwika izi wamba, opanga akhoza kukwaniritsa zotsatira zabwino mu ntchito laser kudula. Kukhazikitsa mayankho odalirika oziziritsa, monga ma laser chillers a mafakitale , kumawonjezeranso mtundu wazinthu, kukhazikika kwazinthu, komanso moyo wautali wa zida.

Tabwera chifukwa cha inu mukadzatifuna.

Chonde lembani fomu yolumikizana nafe, ndipo tidzakhala okondwa kukuthandizani.