Laser cutting may encounter issues like burrs, incomplete cuts, or large heat-affected zones due to improper settings or poor heat management. Identifying root causes and applying targeted solutions, such as optimizing power, gas flow, and using a laser chiller, can significantly improve cutting quality, precision, and equipment lifespan.

Common Defects in Laser Cutting and How to Prevent Them

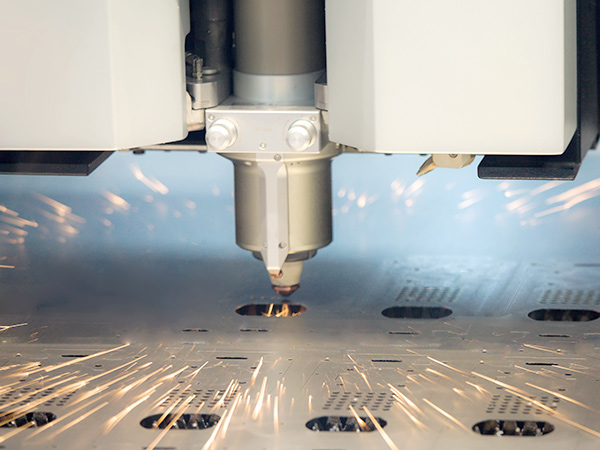

Laser cutting is a widely used technique in modern manufacturing, known for its precision and efficiency. However, if not properly controlled, several defects may arise during the process, affecting product quality and production efficiency. Below are the most common laser cutting defects, their causes, and effective solutions.

1. Rough Edges or Burrs on Cut Surface

Causes: 1) Improper power or cutting speed, 2) Incorrect focal distance, 3) Low gas pressure, 4) Contaminated optics or components

Solutions: 1) Adjust laser power and speed to match the material thickness, 2) Calibrate the focal distance accurately, 3) Clean and maintain the laser head regularly, 4) Optimize gas pressure and flow parameters

2. Dross or Porosity

Causes: 1) Insufficient gas flow, 2) Excessive laser power, 3) Dirty or oxidized material surface

Solutions: 1) Increase the assist gas flow rate, 2) Lower laser power as needed, 3) Ensure material surfaces are clean before cutting

3. Large Heat-Affected Zone (HAZ)

Causes: 1) Excessive power, 2) Slow cutting speed, 3) Inadequate heat dissipation

Solutions: 1) Reduce power or increase speed, 2) Use a laser chiller to control temperature and improve heat management

4. Incomplete Cuts

Causes: 1) Insufficient laser power, 2) Beam misalignment, 3) Worn or damaged nozzle

Solutions: 1) Check and replace the laser source if aging, 2) Realign the optical path, 3) Replace focus lenses or nozzles if worn

5. Burrs on Stainless Steel or Aluminum

Causes: 1) High reflectivity of the material, 2) Low purity of assist gas

Solutions: 1) Use high-purity nitrogen gas (≥99.99%), 2) Adjust focus position for cleaner cuts

The Role of Industrial Laser Chillers in Improving Cutting Quality

Laser chillers play a critical role in minimizing defects and ensuring consistent cutting performance by offering the following benefits:

- Minimizing Heat-Affected Zones: Circulating cooling water absorbs excess heat, reducing thermal deformation and microstructural changes in materials.

- Stabilizing Laser Output: Accurate temperature control keeps laser power stable, preventing burrs or rough edges caused by power fluctuations.

- Extending Equipment Lifespan: Efficient cooling reduces wear on the laser head and optical components, minimizing overheating risks and improving overall efficiency.

- Enhancing Cutting Precision: Chilled work surfaces minimize material warping, while a stable thermal environment ensures vertical laser beams and clean, accurate cuts.

By identifying and addressing these common defects, manufacturers can achieve better results in laser cutting operations. Implementing reliable cooling solutions, such as industrial laser chillers, further enhances product quality, process stability, and equipment longevity.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.