Laser yekucheka inogona kusangana nenyaya senge maburrs, kucheka kusina kukwana, kana nzvimbo dzakakura dzakakanganiswa nekupisa nekuda kwezvirongwa zvisina kunaka kana kusasimba kwekupisa. Kuziva midzi zvikonzero uye kushandisa zvakanangwa zvigadziriso, senge optimization simba, gasi kuyerera, uye kushandisa laser chiller, zvinogona zvakanyanya kunatsiridza kucheka mhando, chaiyo, uye hupenyu hwemidziyo.

Zvakajairwa Kukanganisa muLaser Kucheka uye Maitiro Ekudzivirira Nadzo

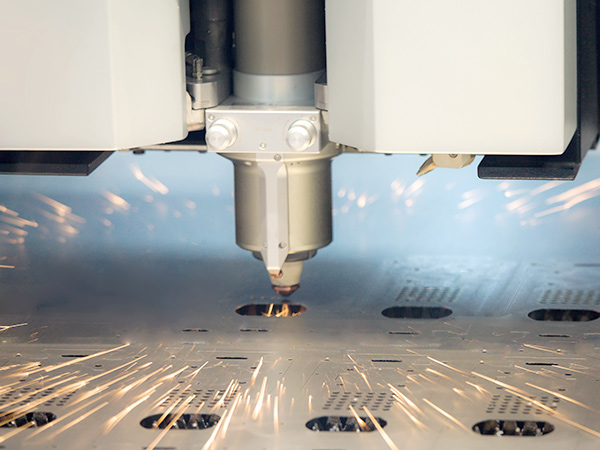

Laser yekucheka inzira inoshandiswa zvakanyanya mukugadzira kwemazuva ano, inozivikanwa nekunyatso uye kushanda kwayo. Nekudaro, kana isina kudzorwa nemazvo, kukanganisa kwakawanda kunogona kumuka panguva yekuita, zvichikanganisa kunaka kwechigadzirwa uye kugona kwekugadzira. Pazasi pane akajairika laser yekucheka kuremara, zvikonzero zvavo, uye inoshanda mhinduro.

1. Rough Edges kana Burrs paCut Surface

Zvinokonzera: 1) Simba risina kunaka kana kukurumidza kucheka, 2) Kutadza kutarisa kure, 3) Kuderera kwegesi, 4) Optics yakasvibiswa kana zvikamu.

Mhinduro: 1) Gadzirisa simba relaser uye nekumhanyisa kuti ienderane neukobvu hwezvinhu, 2) Gadzirisa iyo yakatarisana chinhambwe nenzira kwayo, 3) Chenesa uye chengetedza iyo laser musoro nguva dzose, 4) Gadzirisa gasi kudzvanywa uye kuyerera paramita.

2. Dross kana Porosity

Zvinokonzera: 1) Kusakwana gasi kuyerera, 2) Yakawandisa laser simba, 3) Yakasviba kana oxidized zvinhu pamusoro

Mhinduro: 1) Wedzera iyo yekubatsira gasi kuyerera mwero, 2) Yakaderera laser simba sezvinodiwa, 3) Ita shuwa kuti nzvimbo dzepasi dzakachena usati wacheka.

3. Nzvimbo Yakakura Yakakanganiswa Kupisa (HAZ)

Zvinokonzera: 1) Simba rakawandisa, 2) Kunonoka kucheka kunononoka, 3) Kusakwana kwekupisa kupisa

Solutions: 1) Deredza simba kana kuwedzera kumhanya, 2) Shandisa laser chiller kudzora tembiricha uye kunatsiridza kupisa kutonga.

4. Kuchekwa Kusina Kukwana

Zvinokonzera: 1) Simba relaser rakakwana, 2) Beam misalignment, 3) Yakasakara kana kukuvadzwa nozzle.

Mhinduro: 1) Tarisa uye kutsiva iyo laser sosi kana kuchembera, 2) Gadzirisa nzira yemaziso, 3) Tsiva malenzi ekutarisisa kana nozzles kana yakapfekwa.

5. Burrs paStainless Steel kana Aluminium

Zvinokonzera: 1) High reflectivity yezvinhu, 2) Kuchena kwakaderera kwekubatsira gasi

Mhinduro: 1) Shandisa high-purity nitrogen gasi (≥99.99%), 2) Gadzirisa nzvimbo yakatarisa yekucheka kwekuchenesa

Basa reMaindasitiri Laser Chiller muKuvandudza Kucheka Hunhu

Laser chillers inoita basa rakakosha mukuderedza kuremara uye kuve nechokwadi chekucheka kunoenderana nekupa zvinotevera mabhenefiti:

Nekuona uye kugadzirisa izvi zvakajairika kukanganisa, vagadziri vanogona kuwana mhedzisiro iri nani mukucheka laser mashandiro. Kuita zvinovimbika kutonhora zvigadziriso, senge maindasitiri laser chillers , inowedzera kuwedzera chigadzirwa mhando, kugadzikana kwemaitiro, uye hupenyu hurefu hwemidziyo.

Tiripo nokuda kwenyu kana muchitida.

Ndapota zadza fomu kuti ubate nesu, uye isu tichafara kukubatsira.